Supercharged K20a2 Vtec - Race Spec

#586

Posted 24 January 2011 - 07:41 PM

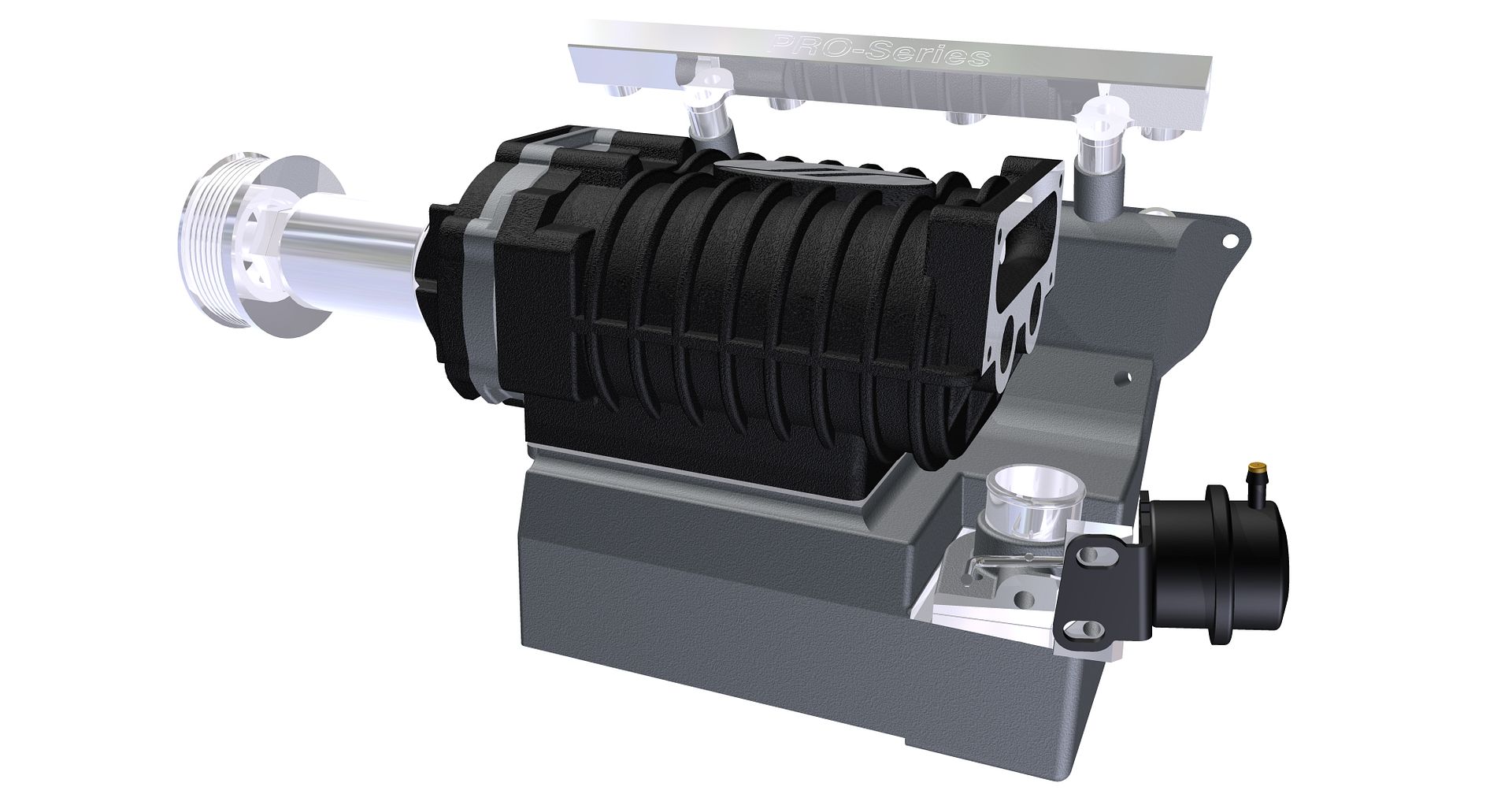

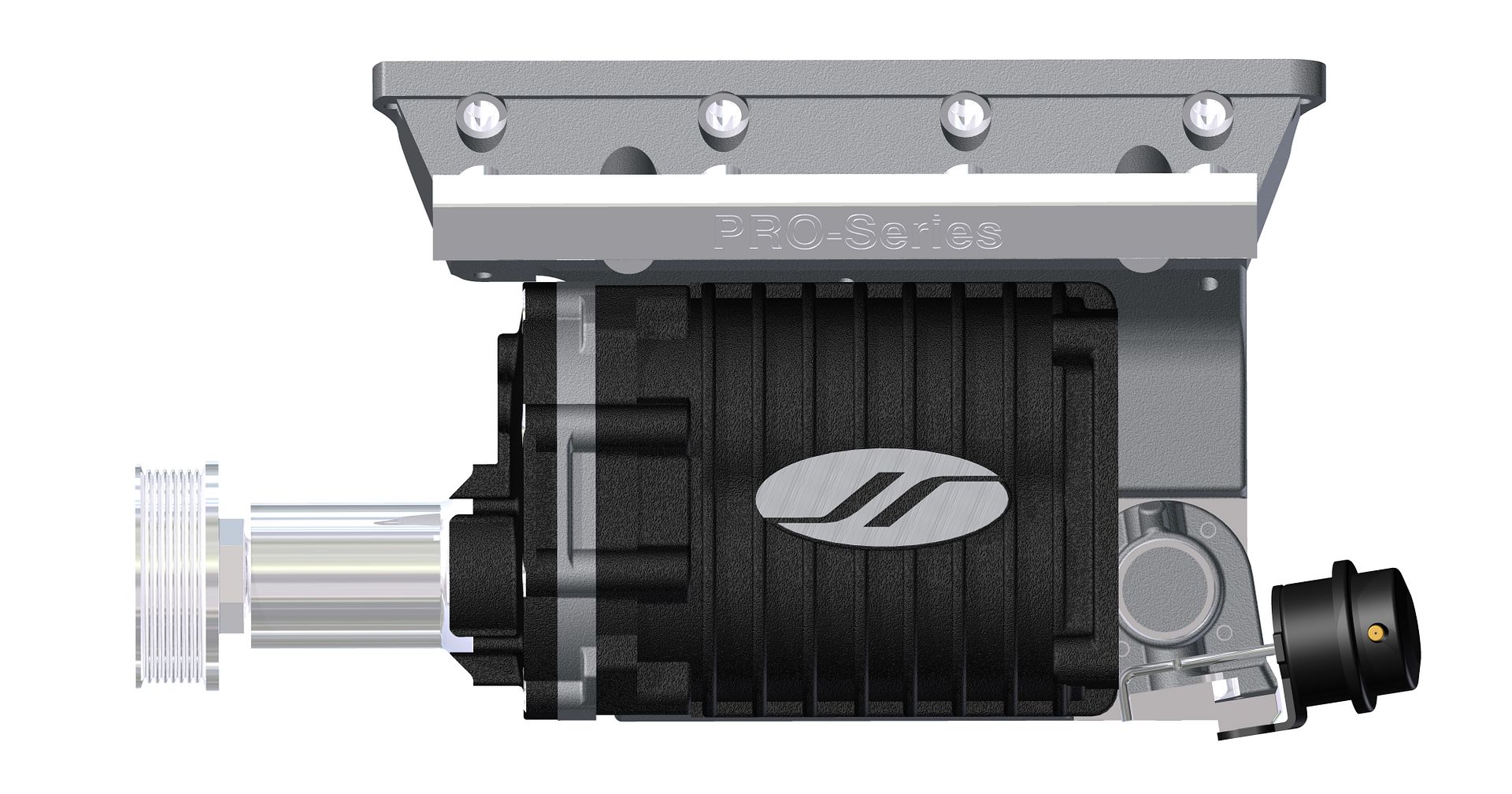

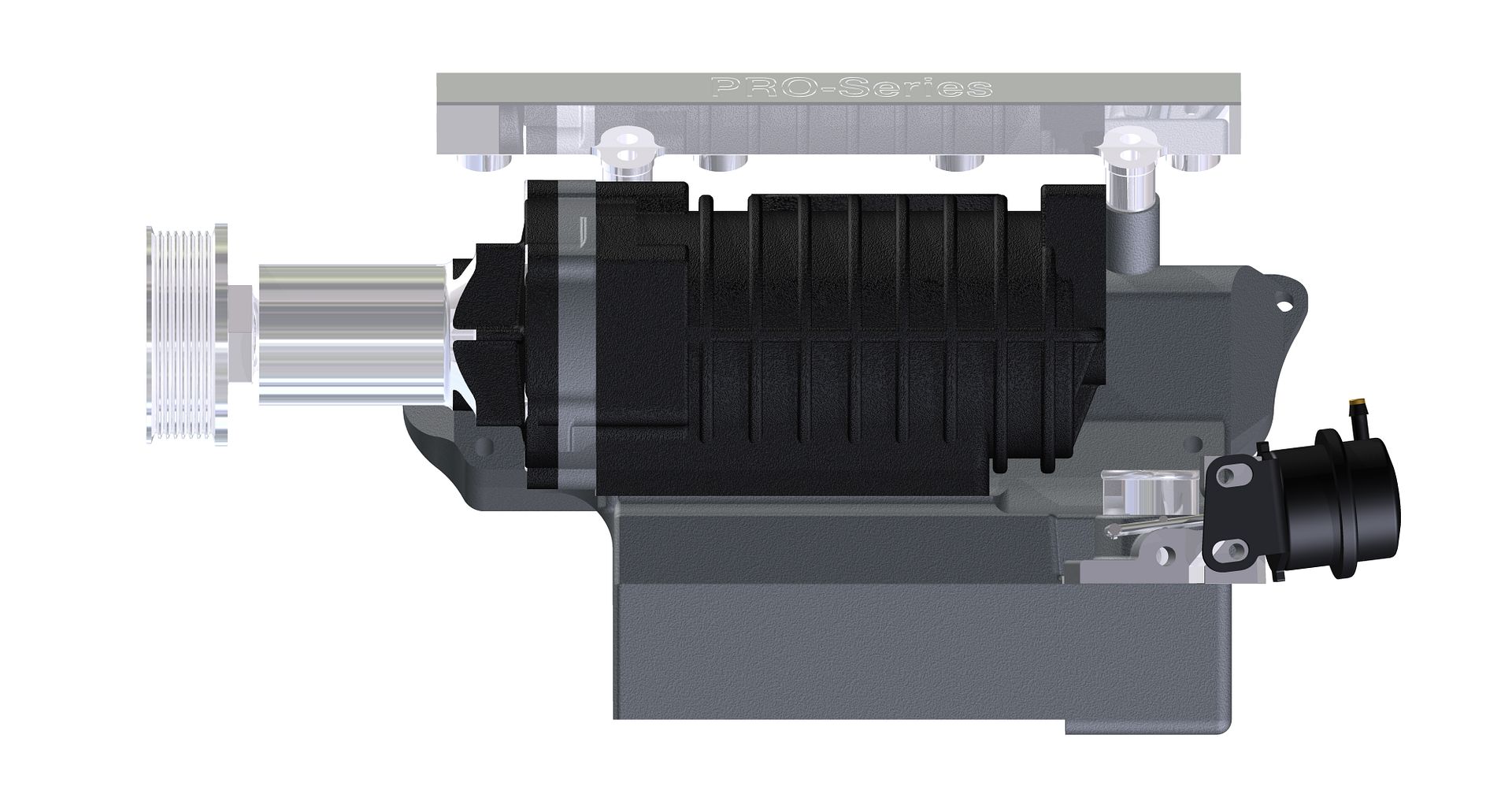

These were done in Autodesk Inventor, its way better for 3D stuff although ACAD is getting better but its not parametric so its way harder to make changes.

I am off the booze at the minute so I find myself needing to fill the after work hours or I'll go mad. I am currently drawing up the manifold which is proving considerably more difficult than the charger.

#587

Posted 27 January 2011 - 09:54 PM

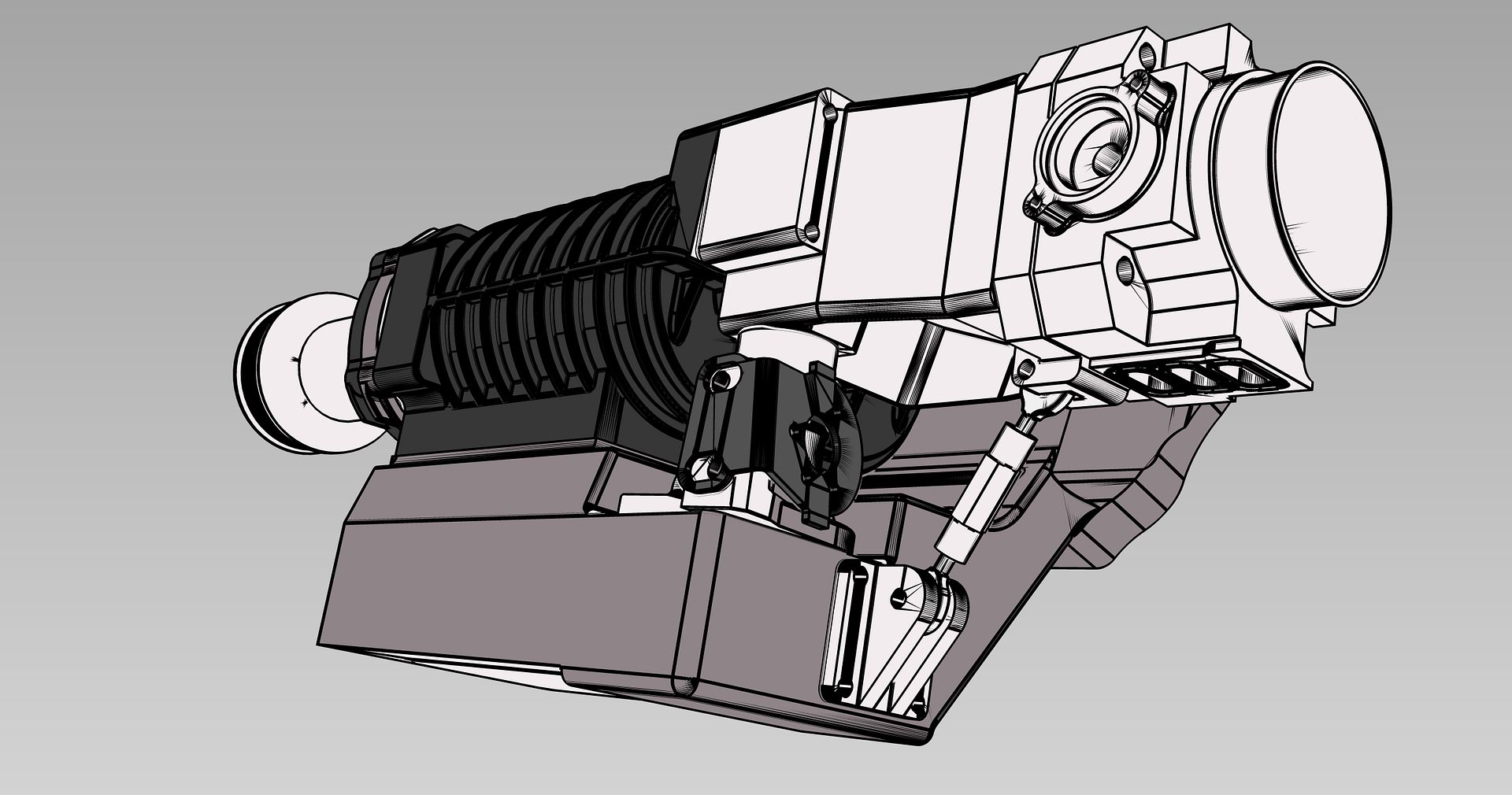

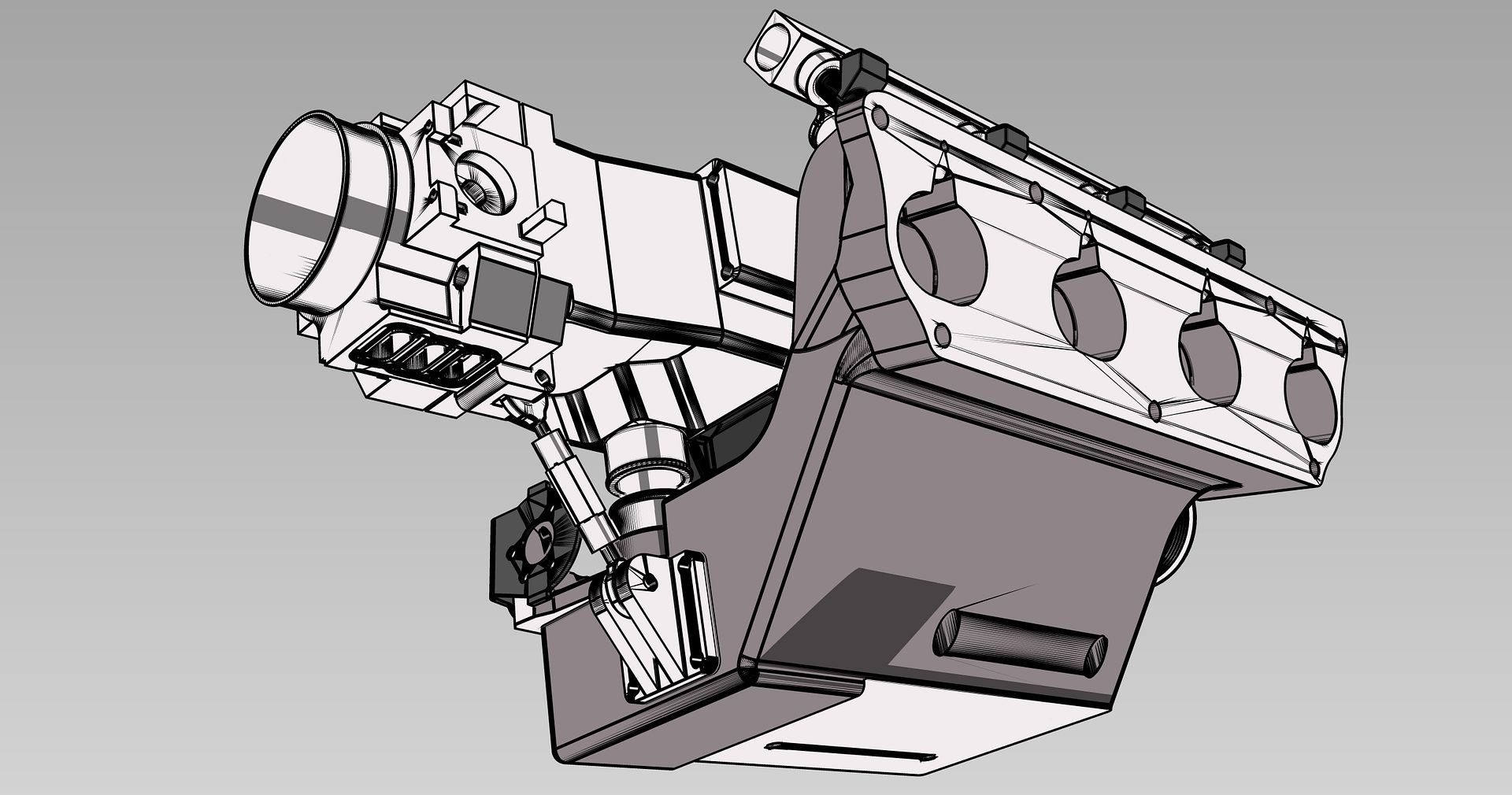

Heres the progress so far:

#588

Posted 27 January 2011 - 10:13 PM

#589

Posted 28 January 2011 - 11:38 AM

I just got my new 72mm Throttle body through......

#590

Posted 28 January 2011 - 11:39 AM

Crazy skills and love the detail

. Wish I could do that sort of thing

Cheers Kev

#591

Posted 29 January 2011 - 11:52 AM

WOO HOO

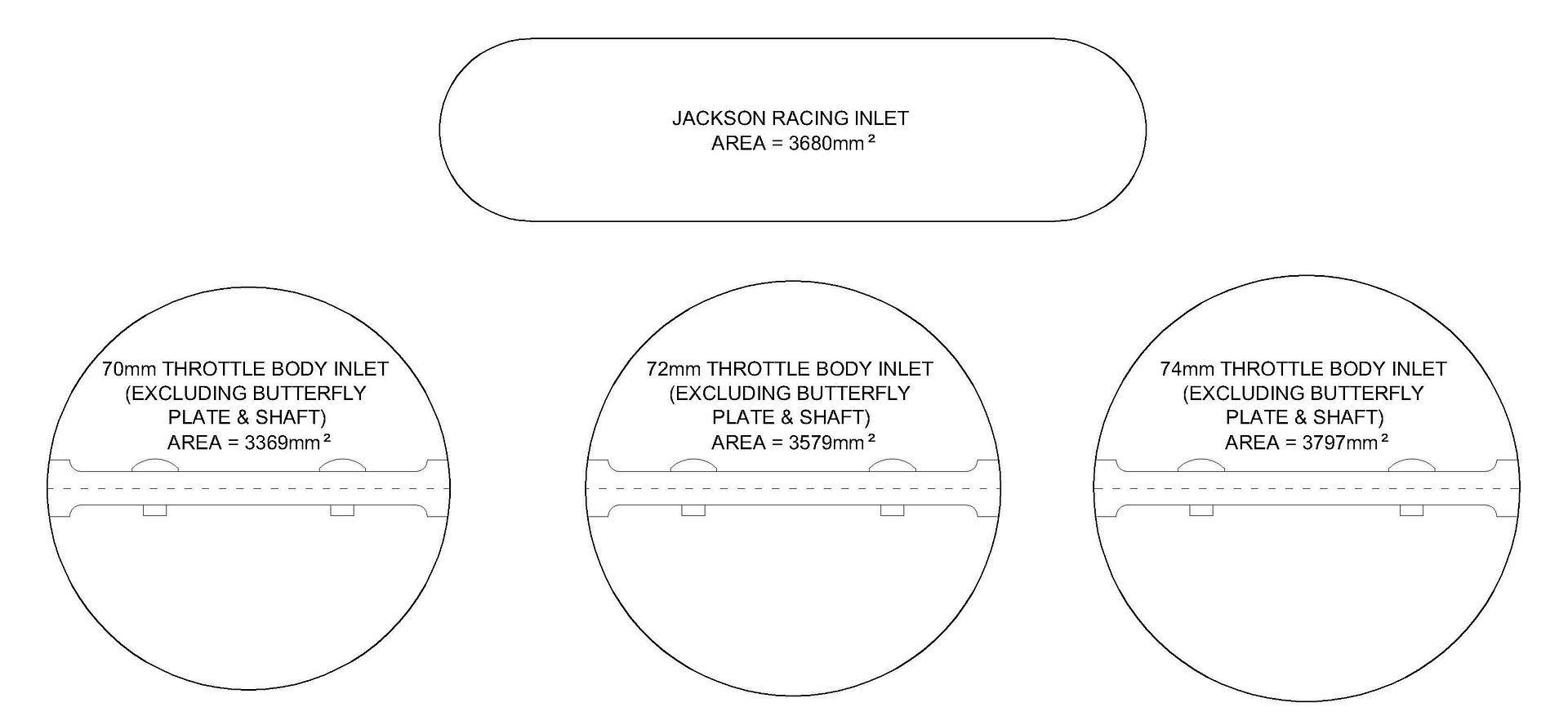

I just got my new 72mm Throttle body through......

BOOOOOOO

The idiots sent me a 70mm and as you can see from the working out drawing below it is not the match of the 72mm to the charger inlet, some might say i should have gone for the 74mm but I figured the 72 is the compromise between unworkable low revs and unrestricted air flow but I guess thats all in the mapping as well.

That'll be another fortnight waiting for another one and then paying more duty and handling fees - T0ssers.....

#592

Posted 30 January 2011 - 03:24 PM

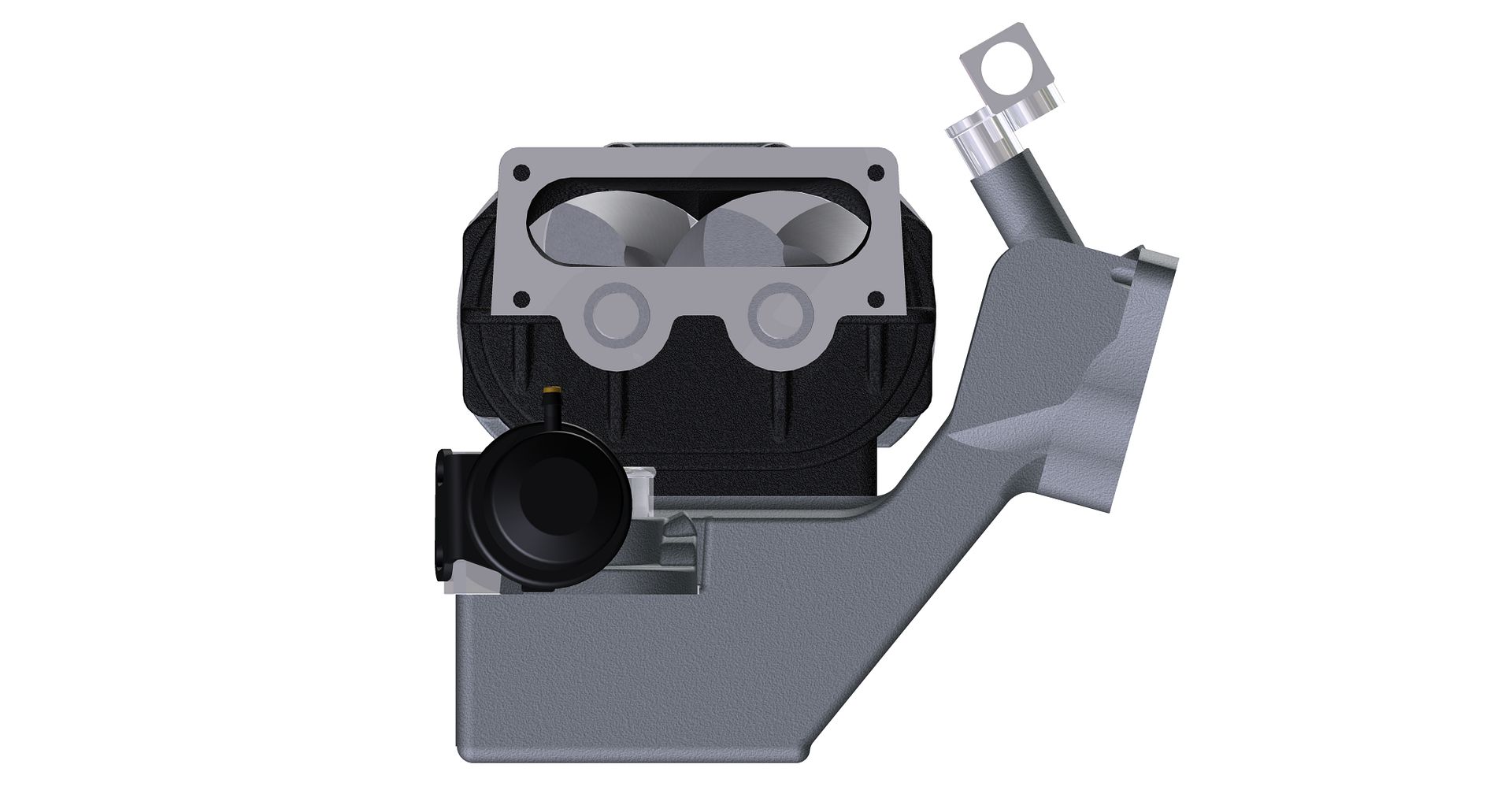

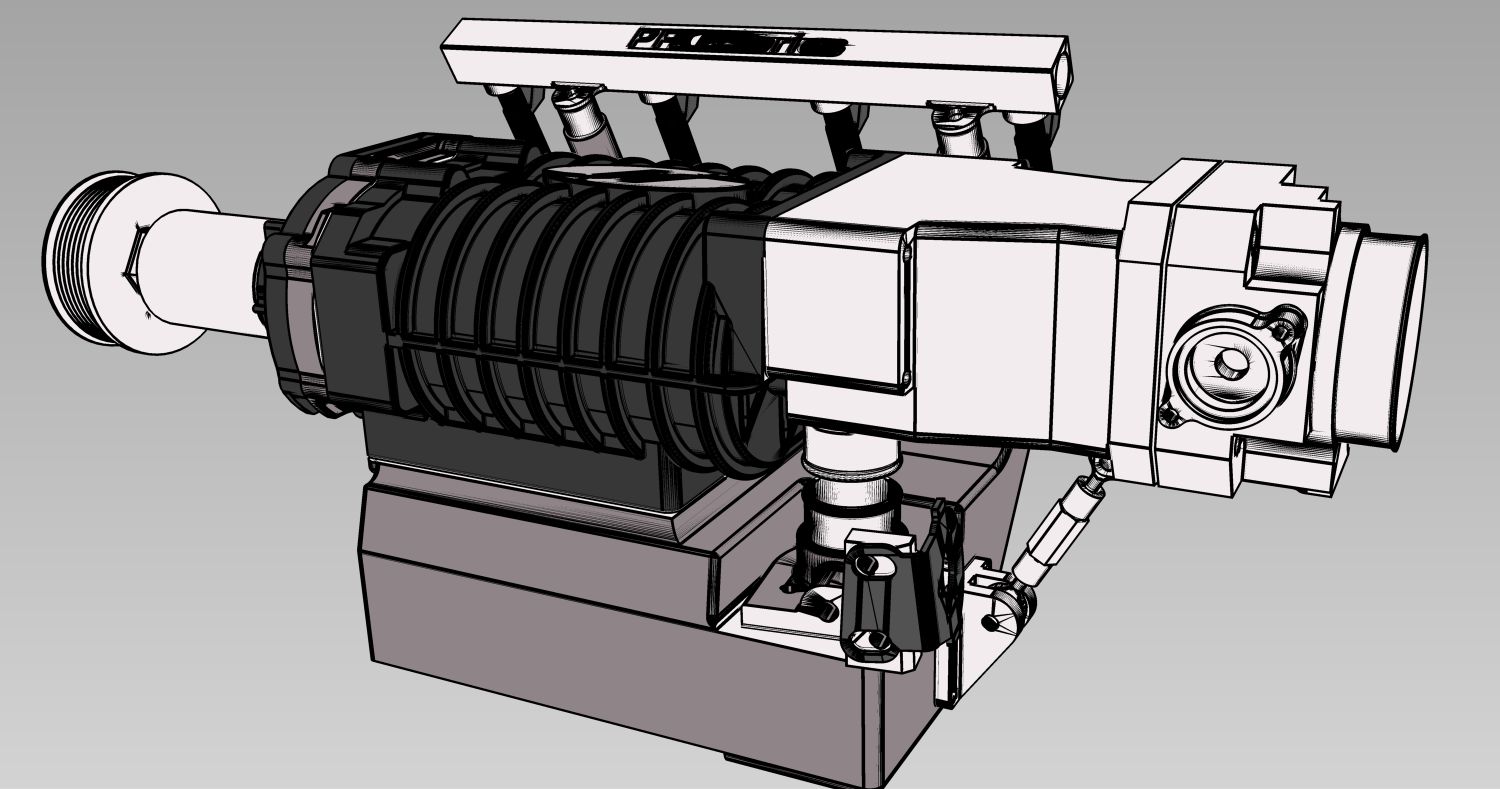

I have what I consider my first true revision of what I would like to have made for my setup.

For the flow through the unit the top of the TB inlet it 5mm higher than the top of the charger inlet so the flow should be really good through the new TB-SC Manifold (thats what I am calling my version of it).

I really tried to consider the production of it on the mill, well on the outer edges anway as theres not much I can about the shape on the inside. The bottom of the manifold sits lower on the charger than the original (covering the front rotor bearings), this will help with the stresses on the bolts in the charger and have supported the TB end with a simple support strut that will have RH/LH threaded rod between the two rose joints. I did this because the weight of the new TB-SC Manifold and the TB was going to be alot more than in the original setup. I removed as much weight as possible from the underneath to help with this. At any point on the model the wall thickness is no less than 5mm.

Its a two piece design with the pipe for the bypass being machined seperately and then held in place with grubs screws and gakset sealant.

I need to get a price for machining now I have something I can give them.

I did a few illustration type renders of it as its easier to see what is going on with the design as things started getting a bit too reflective and shadowy:

#593

Posted 30 January 2011 - 06:53 PM

I just lost mine and I don't know yet for how long.

#594

Posted 31 January 2011 - 08:44 AM

I have a general off-topic question. You all are driving heavily tuned cars, some roadlegal. I don't know the law in the UK, but aren't you affraid to lose your driverslicence?

I just lost mine and I don't know yet for how long.

In answer to your question - Yes, I guess that all depends on how you drive, just because I have a quick car doesnt mean it gets driven at wide open throttle everywhere I go.

#595

Posted 10 February 2011 - 03:18 PM

Things have slowed as I await people getting back to me with regards to machining the new manifold, if only I had my own mill this would be much less painful.

So I sent my recent purchase of the 72mm Tb that turned out to be a 70mm TB and they think that all they have marked as 72's are in fact 70's so I have ahd to order a different make which isnt all bad when I looked at the craftsmanship of the original.

I got my new TPS (throttle position sensor) through today from the good old US of A, it was only £30 summink quid, bargain compared to the Honda stealers oh sorry I meant dealers.....

I ordered my new air filter, its a K&N RX-4730, I am hoping it'll arrive on Monday, so I can start to design the shroud to shield it from the hot air of the engine bay. I only have a picture of it from the tinternet at the moment but you can see it is a proper decent one, I checked with K&N UK and its rated to 660BHP with a S/C or Turbo setup so I am not reaching anywhere near its limits with my current configuration. I am going to measure up the Apollo to see jsut how much difference in surface area there is between the two - will post figures once done...

Here's a snap of it from t'tinternet:

more updates as when stuff arrives.....

.

#596

Posted 10 February 2011 - 03:33 PM

niceCompleted Project Pictures on Pages 29,30 & 31

As most people who start down the route of building or even part building a Zcars mini conversion, you initially ask Chris a few questions, then you go up to Gallows Farm for a tour and a taster in the demo car, were (I think most who have had a demo from Chris will agree) Chris erases any doubt in your head as to whether or not you should buy one of their kits. The fantastic noise, the unbelievable grip, the awesome stopping power of the demo car coupled with Chris's driving skill makes for one of the most exhilirating demo's I've ever had. Oh and dont forget Chris's no bullsh*t sales patter, he's got that down to an art form.

So I was well and truly sold, I simply had to have a Zcars mini. Looking around at the other cars and asking questions of the guys about the cost of building one of the beasts I got an idea of how much I wanted to spend. Then I went home, thought about it, thought about it some more, started to do a few sums and then took the plunge and got Richard to send me a quote.

Upon recieving the quote it dawned on me (some of you who have built one of these are probably gonna laugh in agreement at this statement) that my budget was about double if I was going to get all the things I wanted in the car. When I tell people that I could easily have bought a new Evo X or a very nice second hand Porsche for the money I am spending some scof and think I have lost my marbles, others understand that this is a one off and no-one in the world will have exactly the same car as I will have when I finish this journey, of which I am only halfway along.

So I bought a second hand shell from Chris, which was pretty much sound:

I then decided after driving an Accord Type R for a few years that the VTEC K20A2 from the Civic Type R was going to be the engine of choice, but being a bloke I thought it would be a good idea to get a few extra ponies out of the little 2litre engine so I ordered a Jackson Racing supercharger kit. The kit is for an RSX, American car. I got a couple of snaps of it before I took it to Zcars:

Then the guys strapped it the engine:

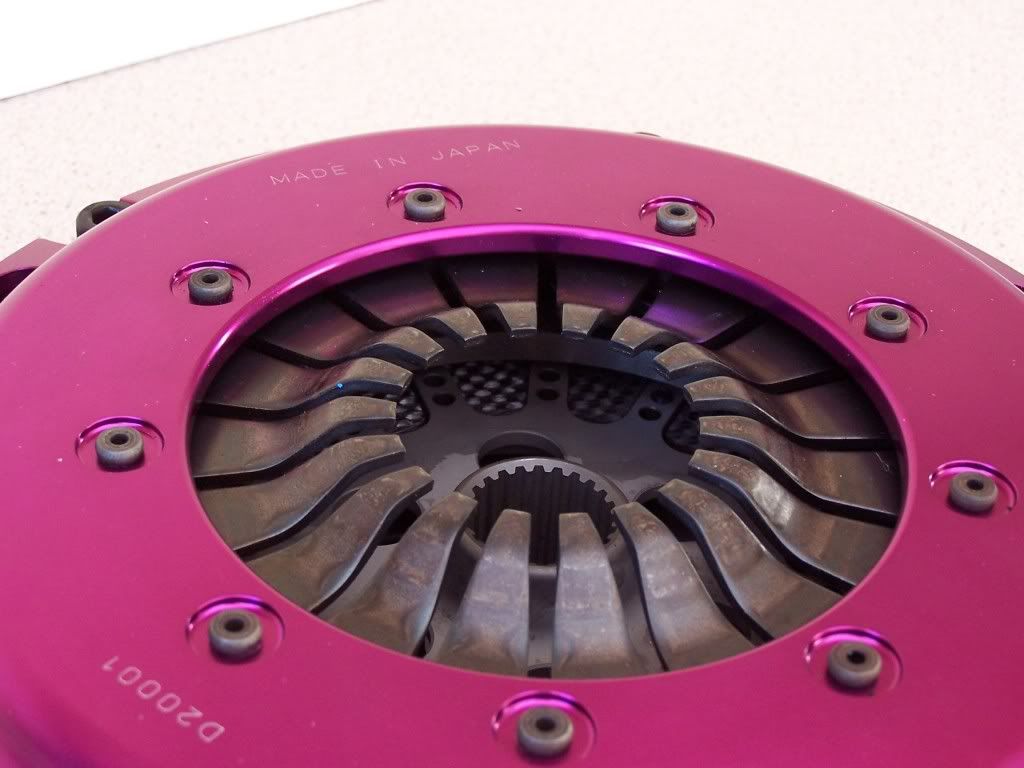

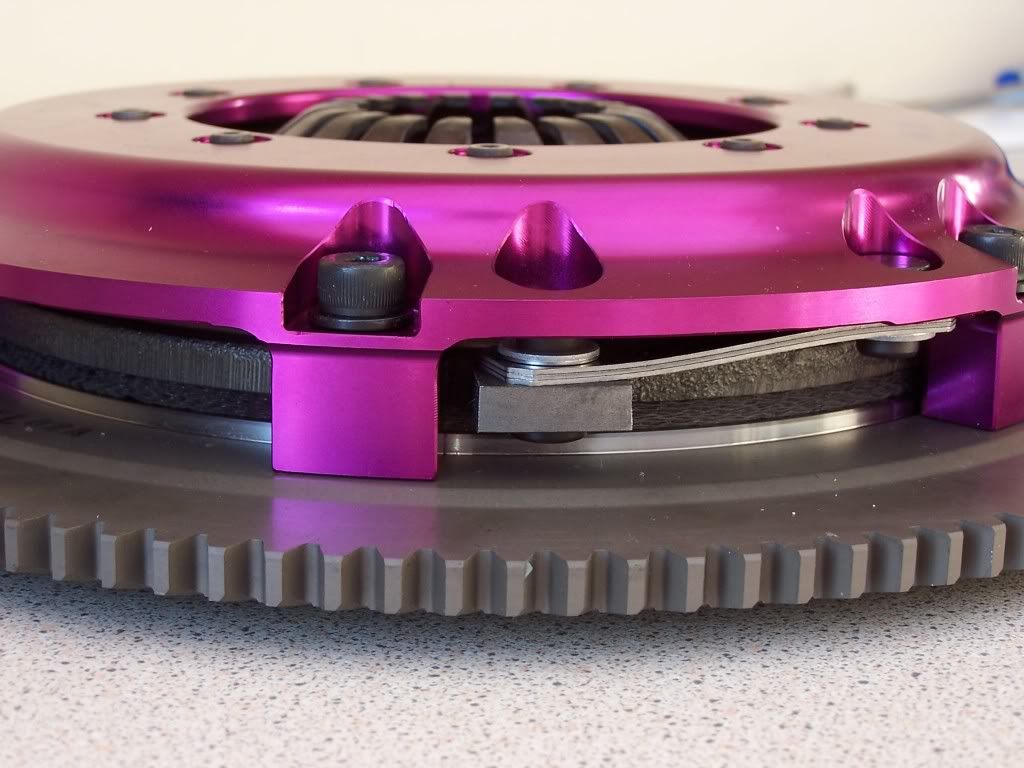

To be able to cope with the extra HP and Torque I opted for an Exedy Single Carbon Hyper Clutch and Flywheel (Part # - HH03SBMC), these things can take a max torque load of 254ft/lb which will give me around 50ft/lb to play with later down the line. I have to say it is quite a sext thing:

I took along time deciding which seats I was going to use, however one thing that really swung it for me (and I know this is fairly shallow of me) was the name of the manufacturer of the seats - Kirkey. How could I not have seats from a namesake? however it wasnt that easy as the Kirkey seats I had seen in some of the minis just did not look comfortable, that whole wrap around the ribs thing wasnt floating my boat. So after many hours on the kirkey website I decided on the Intermediate Road Race seats, they appeared to be the best comprimise between cost and comfort, plus having a larger frame than most I could order them in hip width. So here they are during the seat fitting, ignore the date on the photo + you can see more in later photo's:

Wheels - again a long time deciding but in the end I opted for Image 3 peice Billet 60P, always a sucker for gimmick I thought the idea if drawing air from under the car to aid the cooling of brakes to be a good one especially when telling your mates over a few beers. I went for 7" on the front and 8" on the back. Again ignore the date on the photo.

They are now wrapped in Toyo R888 tires, 185 front and 205 rear.

Arches were going to be a problem with the width of the rear wheels but Zcars came to rescue with the help of THE STIG, top fibreglasser. I would like to thank Chris and THE STIG for their help with getting these together for me. These are a few pictures of the car pre-spray with the new arches:

More on next post

#597

Posted 10 February 2011 - 03:37 PM

#598

Posted 10 February 2011 - 03:41 PM

nice

Wow, that post was October 2008......its been finished almost a year.....I am just adding mods to it now to get more ponies....

#599

Posted 10 February 2011 - 03:45 PM

dude, thats some serious bit of kit that you have there, going to be such a beast when finished

how much torque do you think its going to have?

Its has approx 190lb/ft of torque now - not loads compared to other cars but remember the VTEC revs to 8800rpm....with the proposed modification it should bring it inline with the predicted BHP of 340-345 from 315 so I would stab at the torque going from 190 to around 210-215lb/ft.

Edited by cptkirk, 10 February 2011 - 03:47 PM.

#600

Posted 10 February 2011 - 03:51 PM

You going to many shows this year?

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users