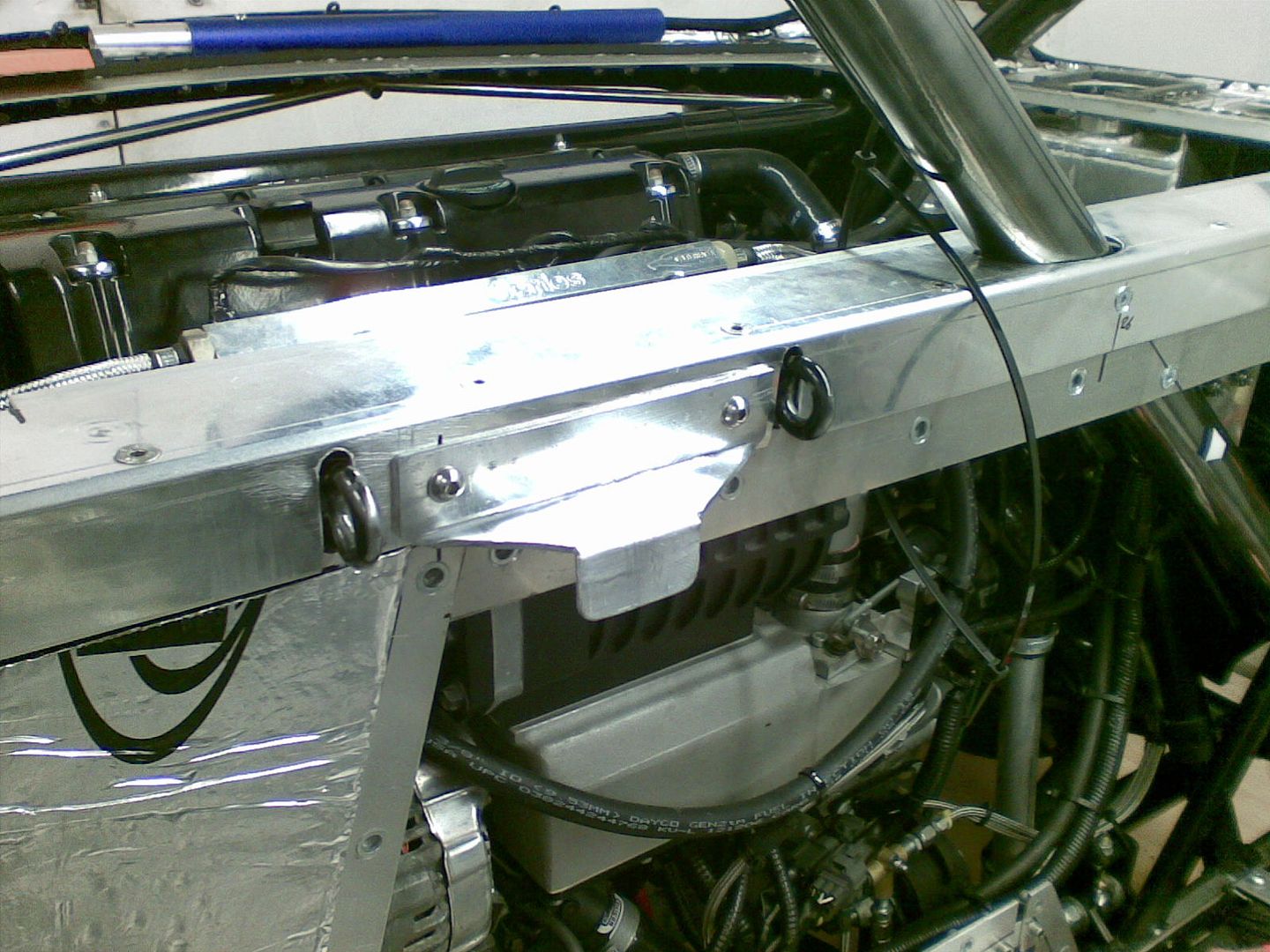

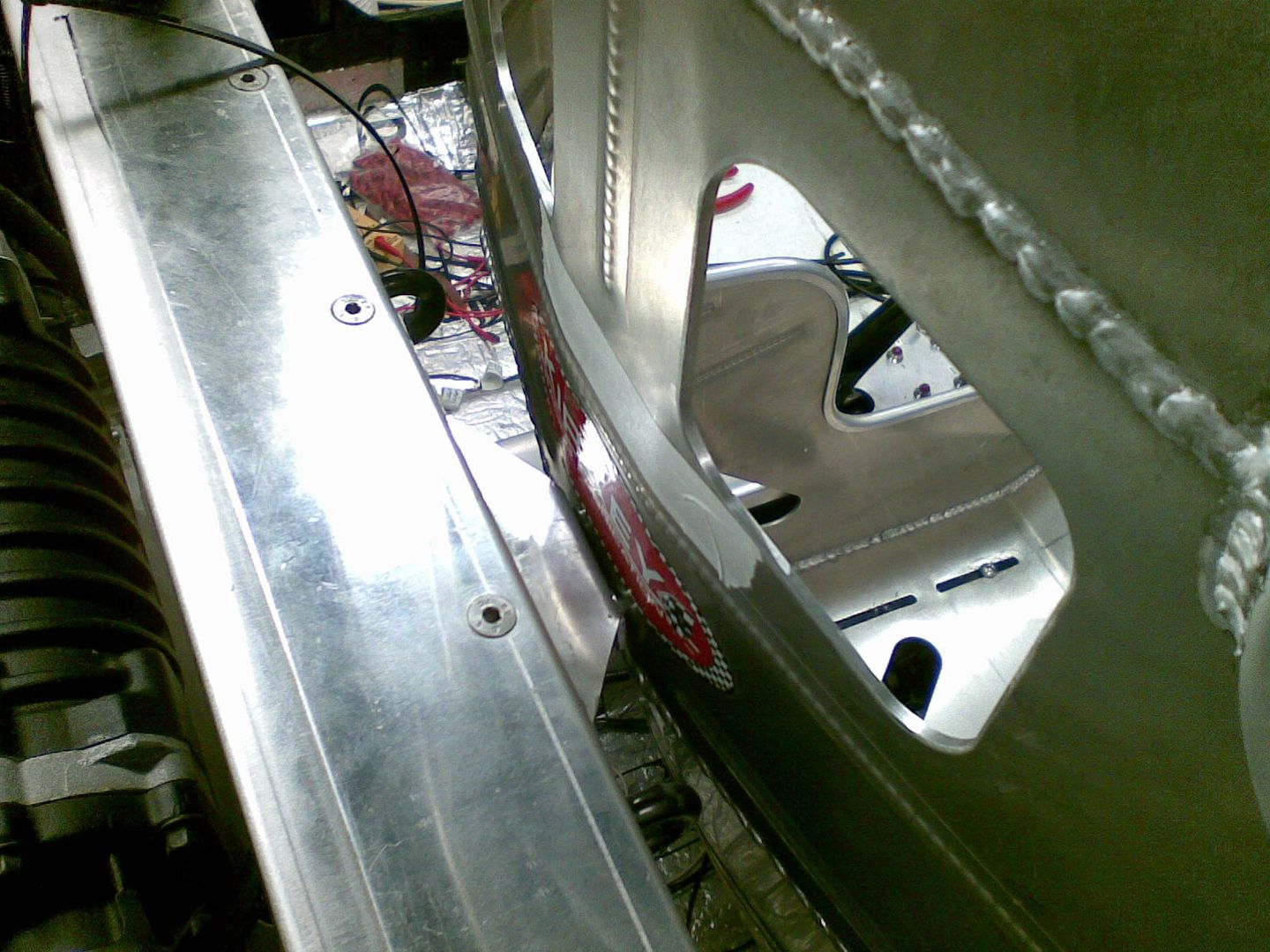

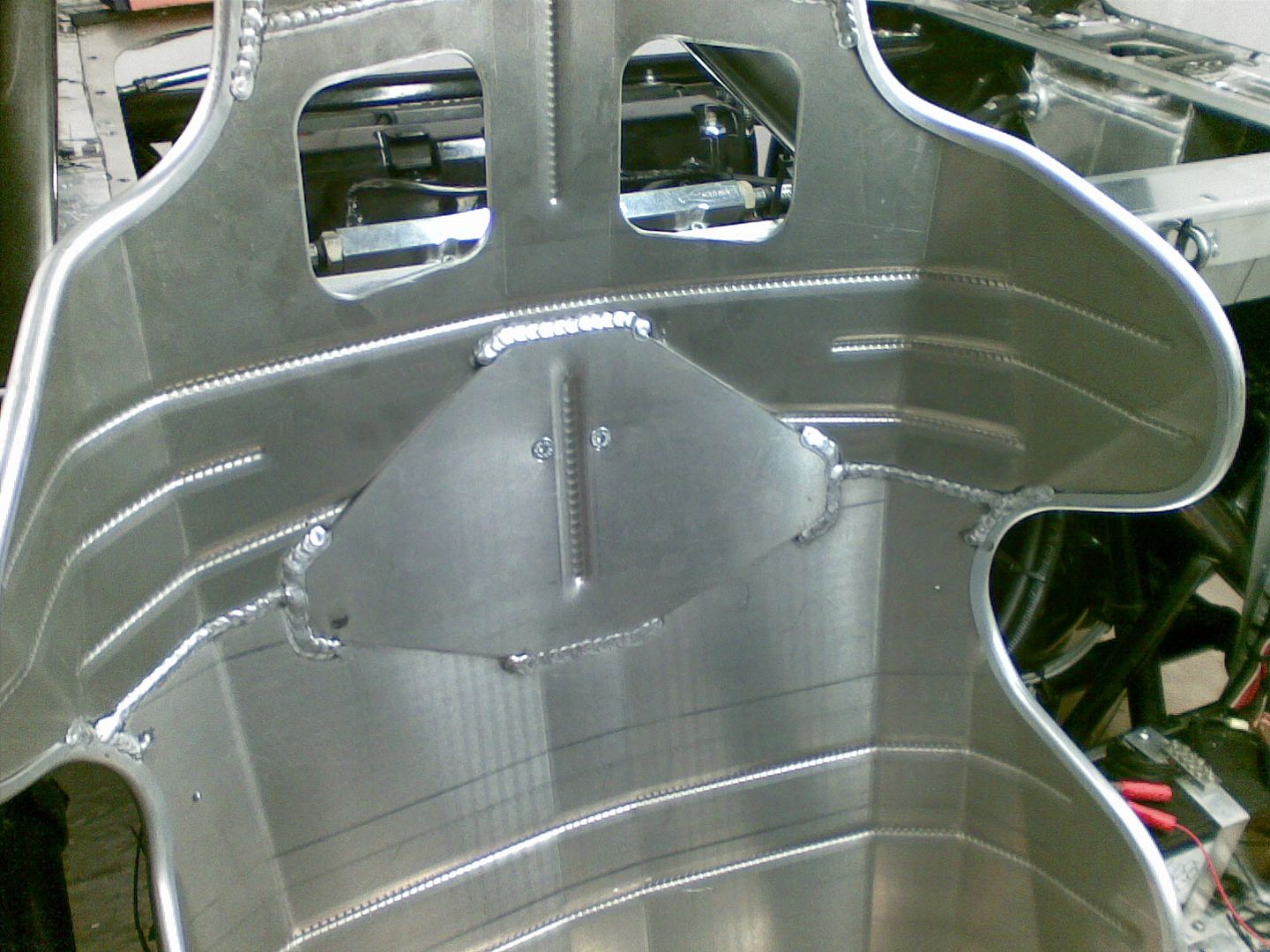

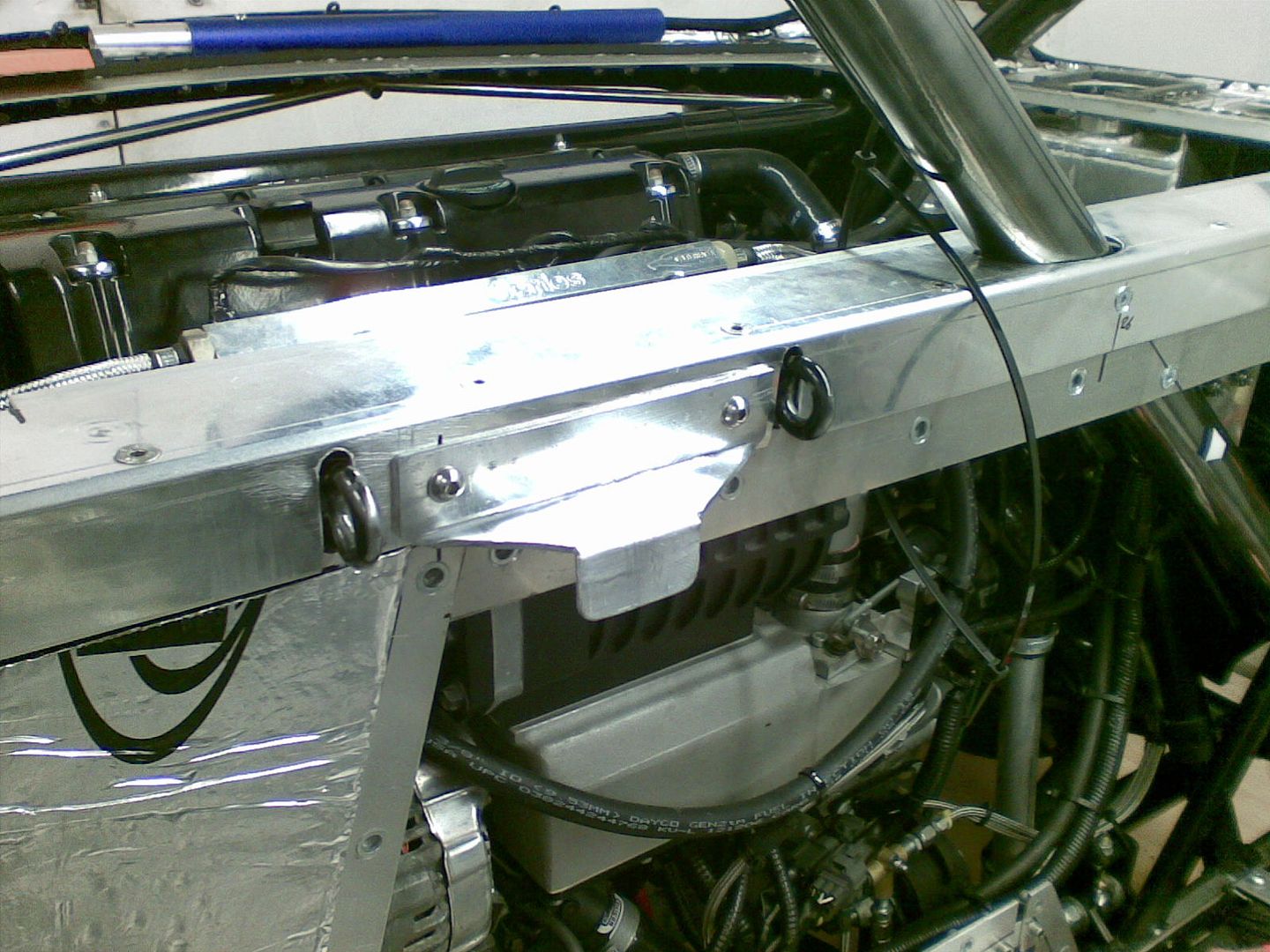

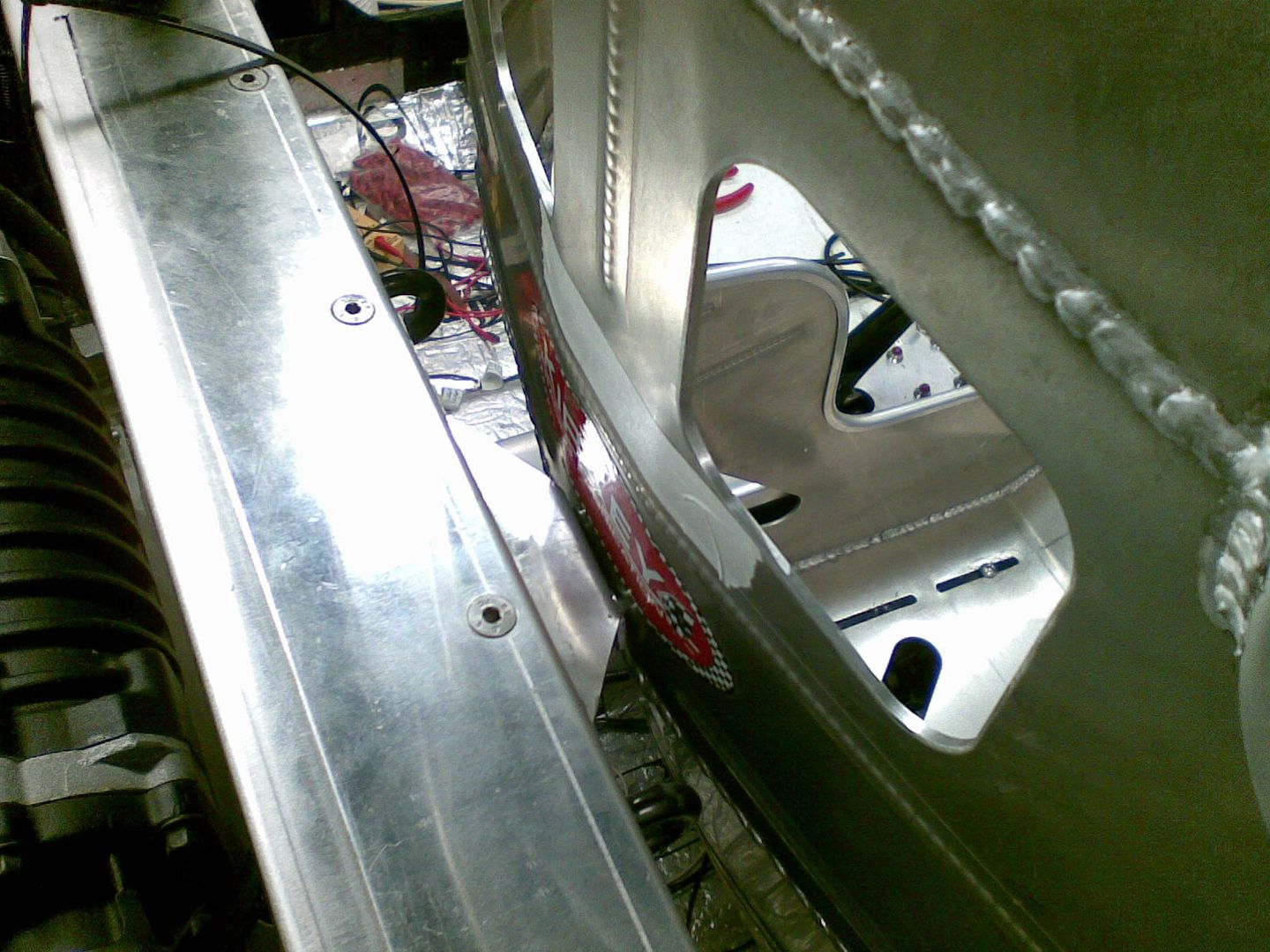

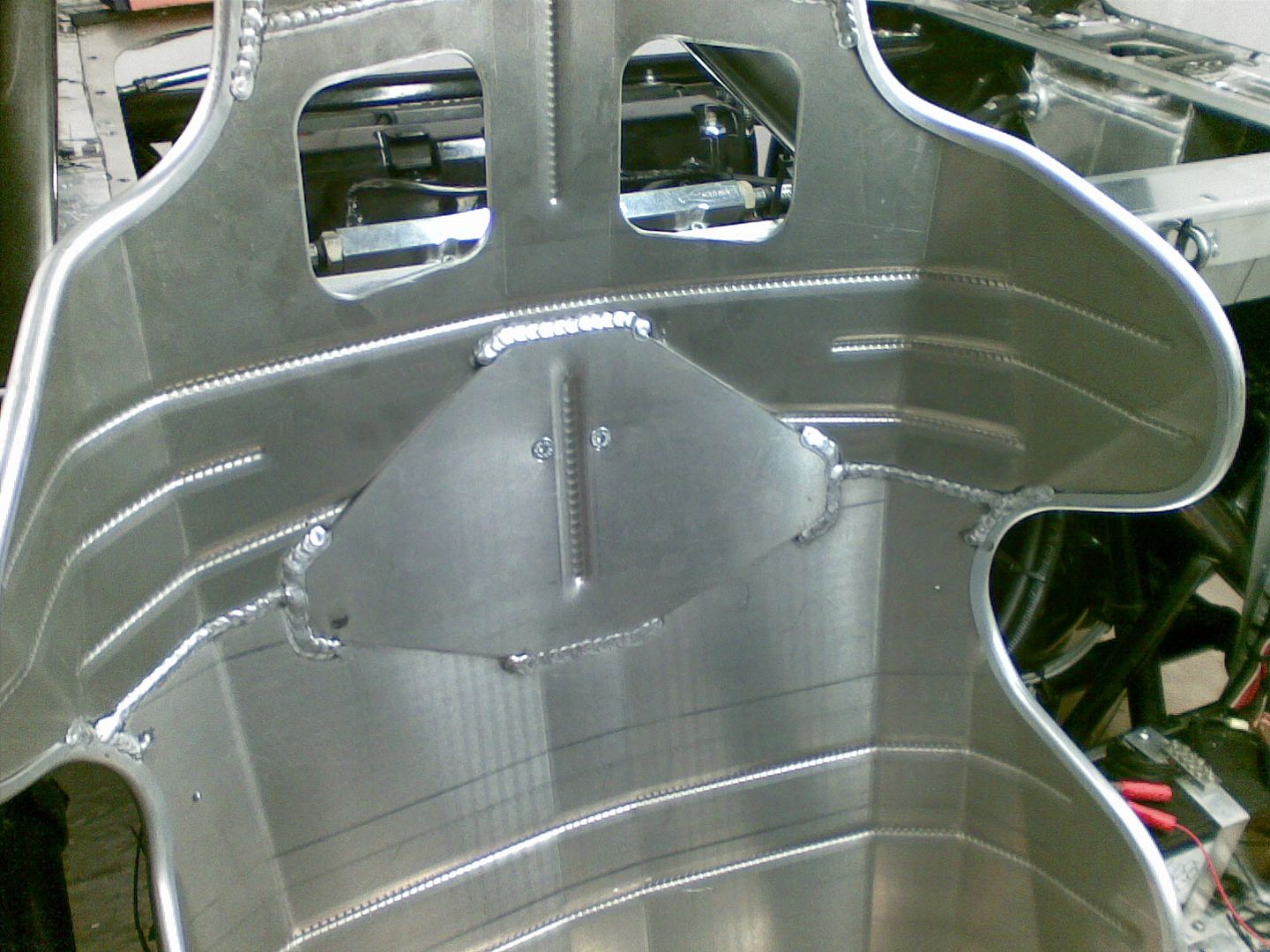

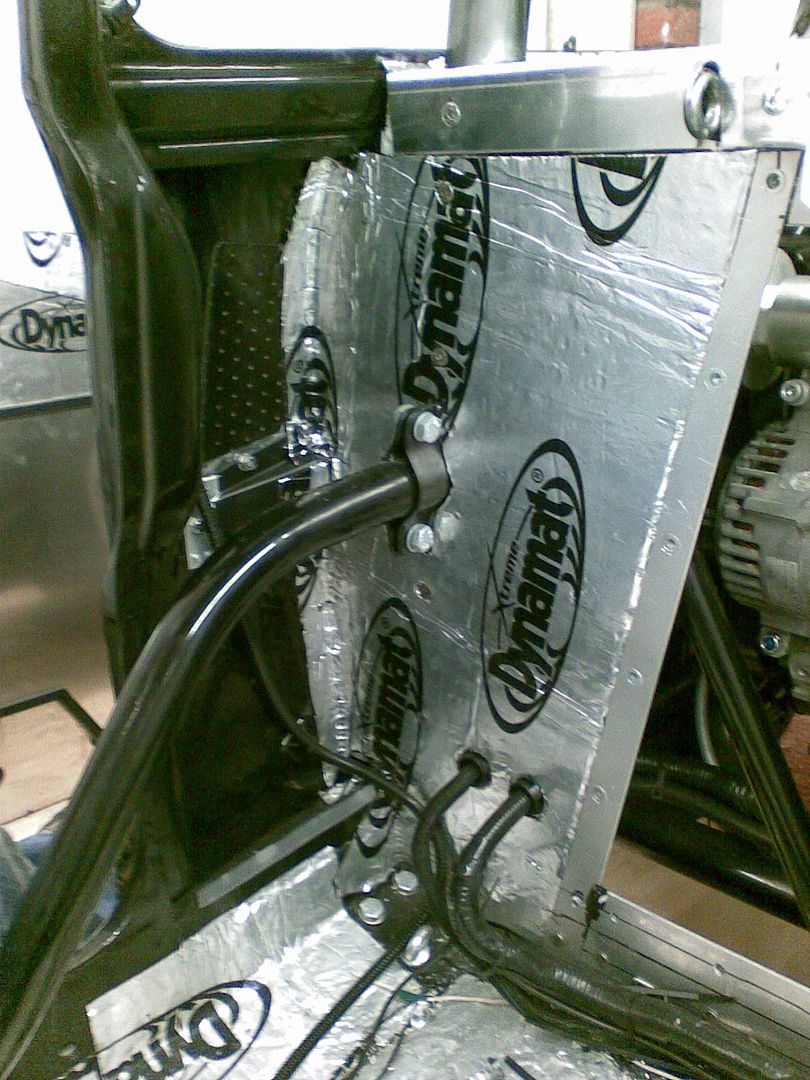

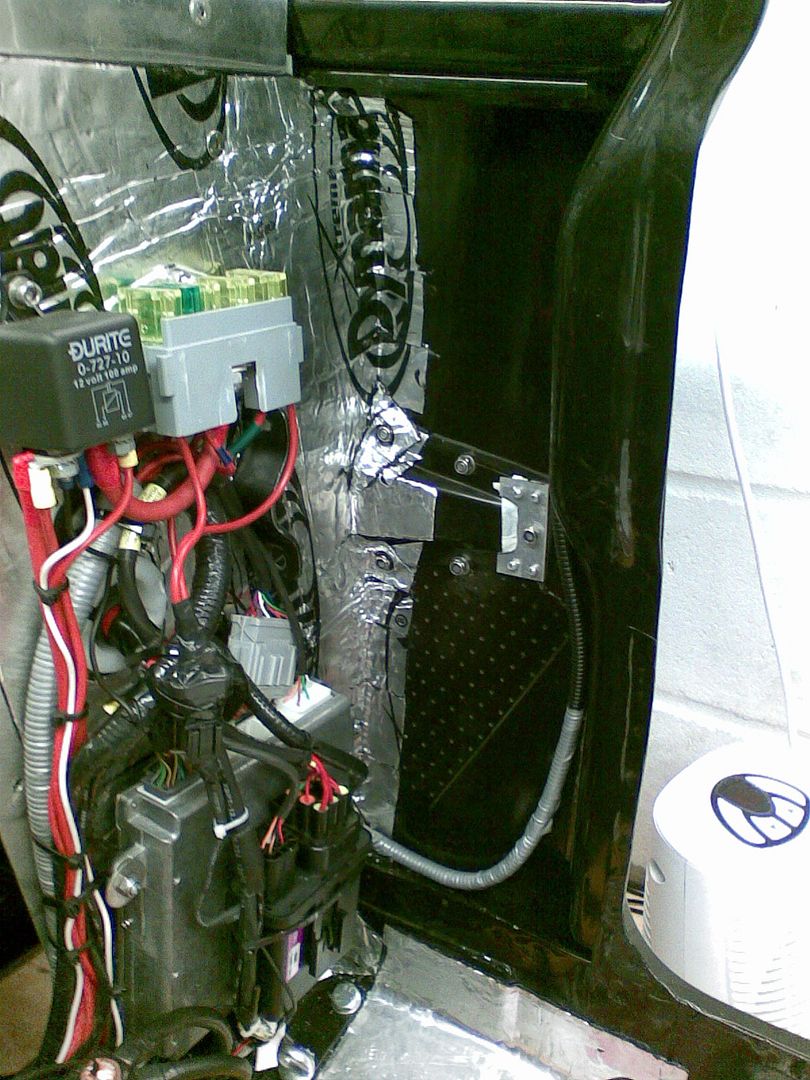

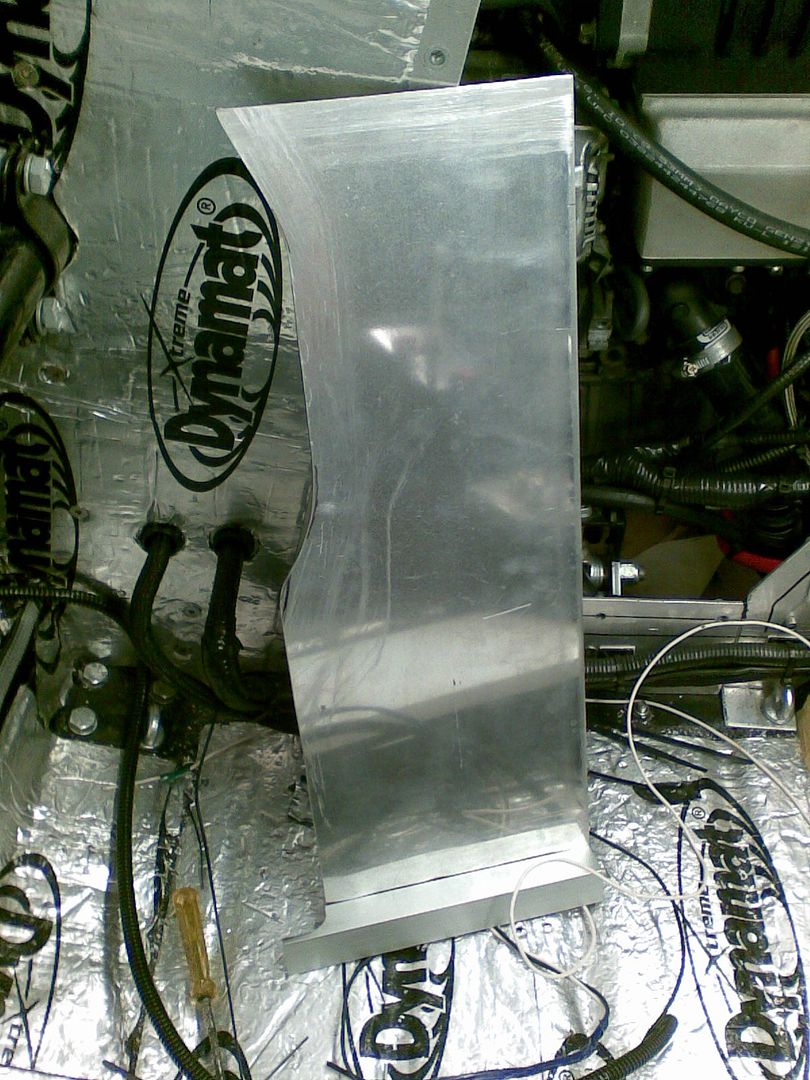

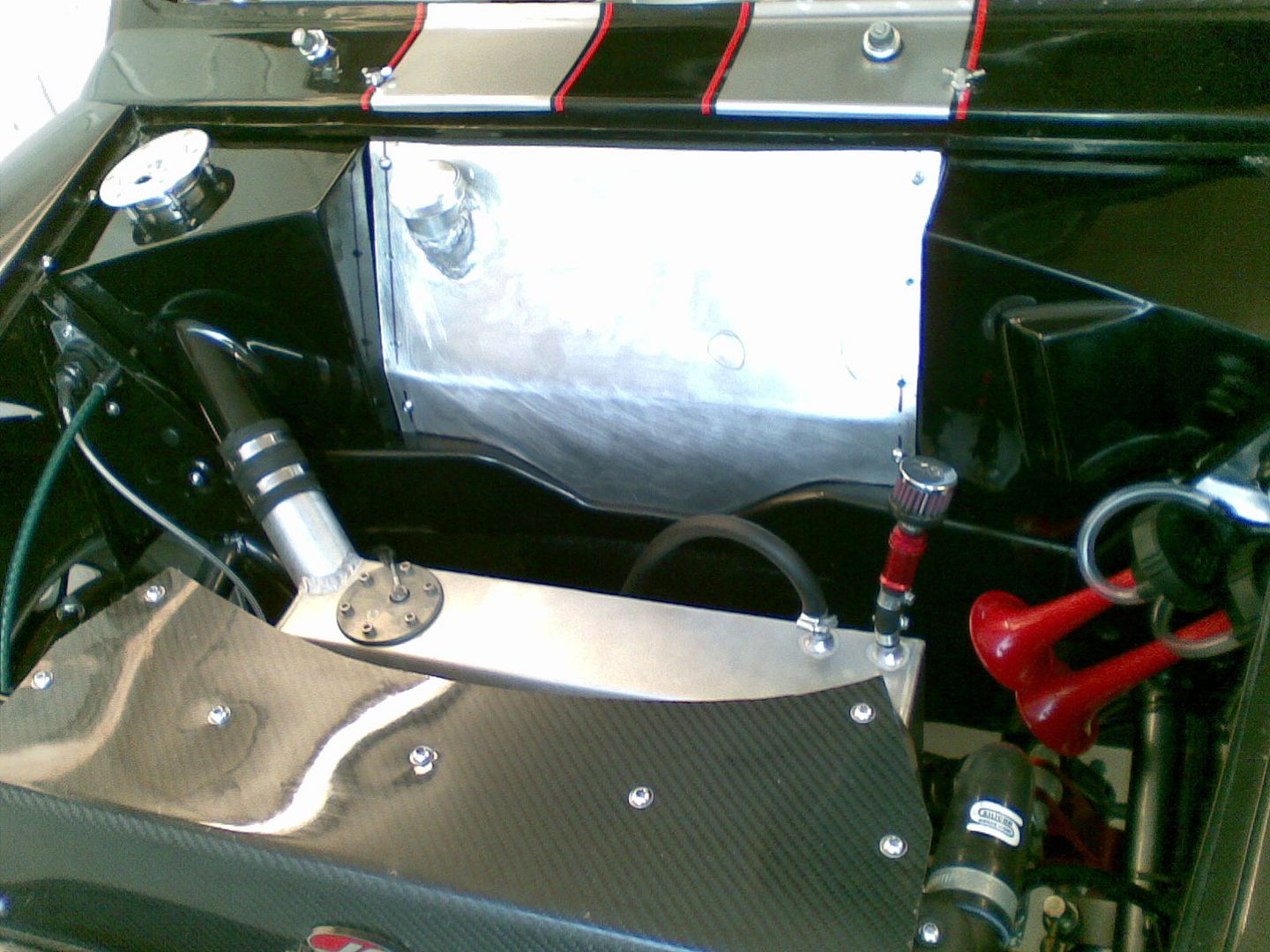

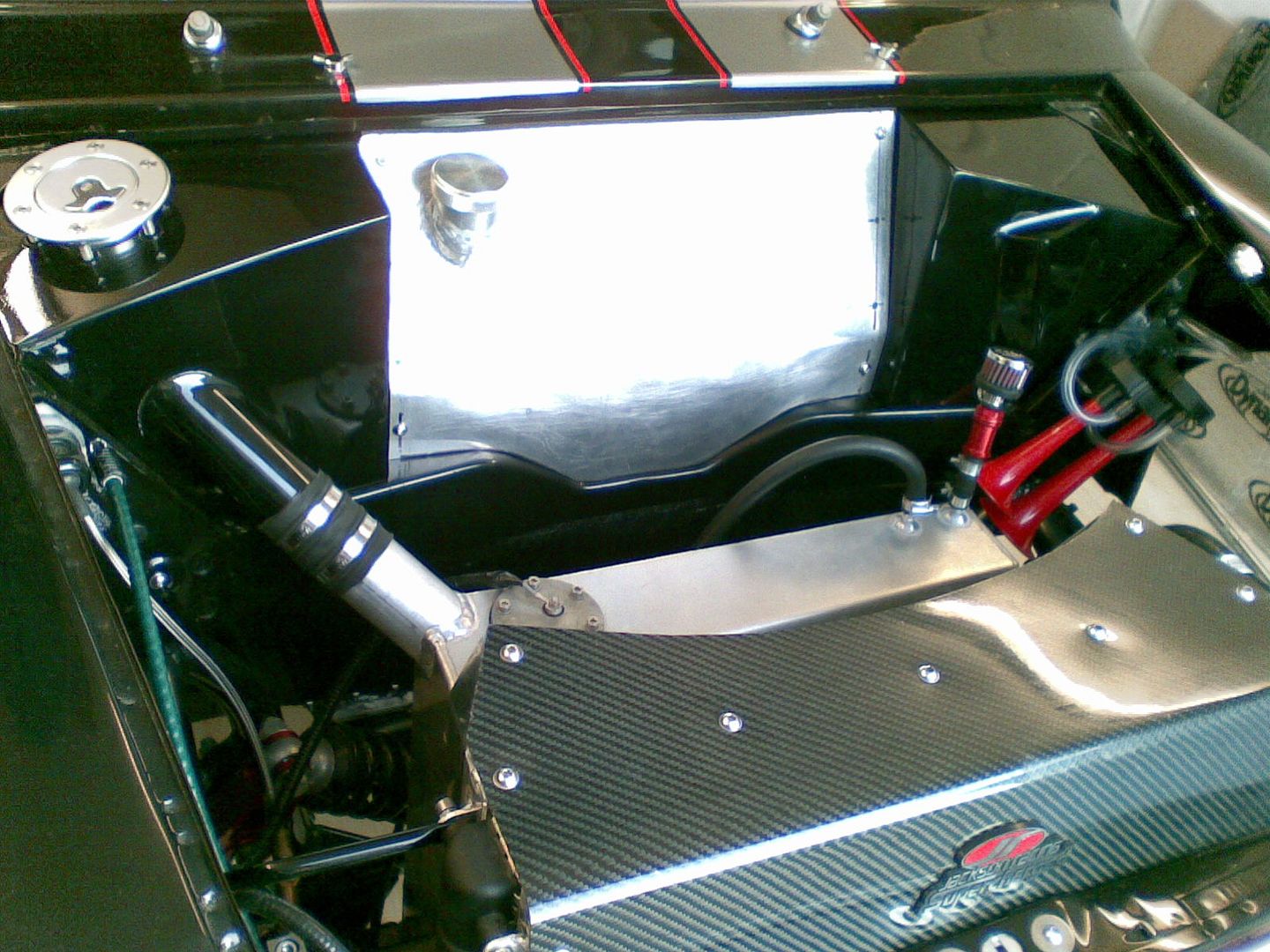

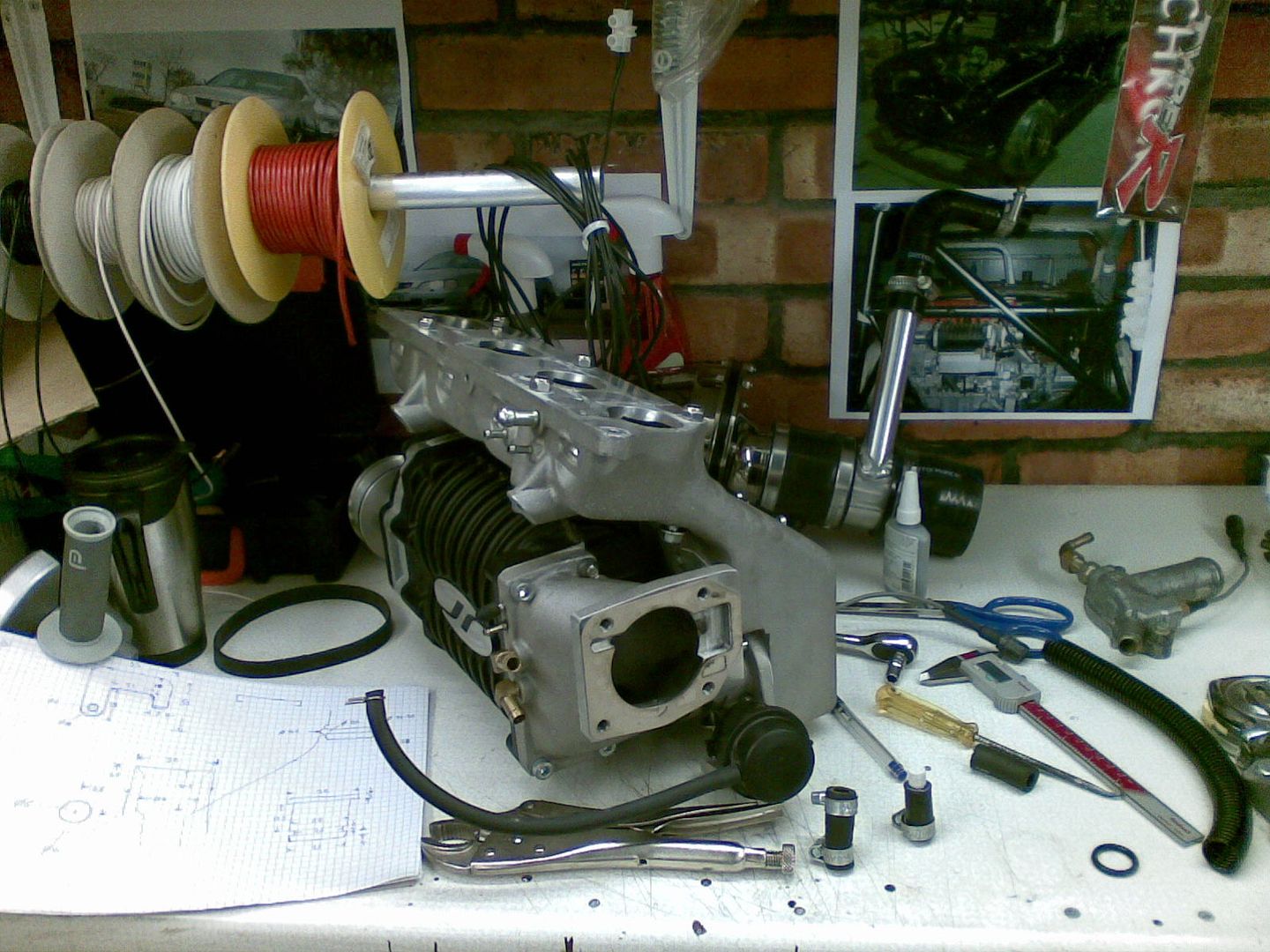

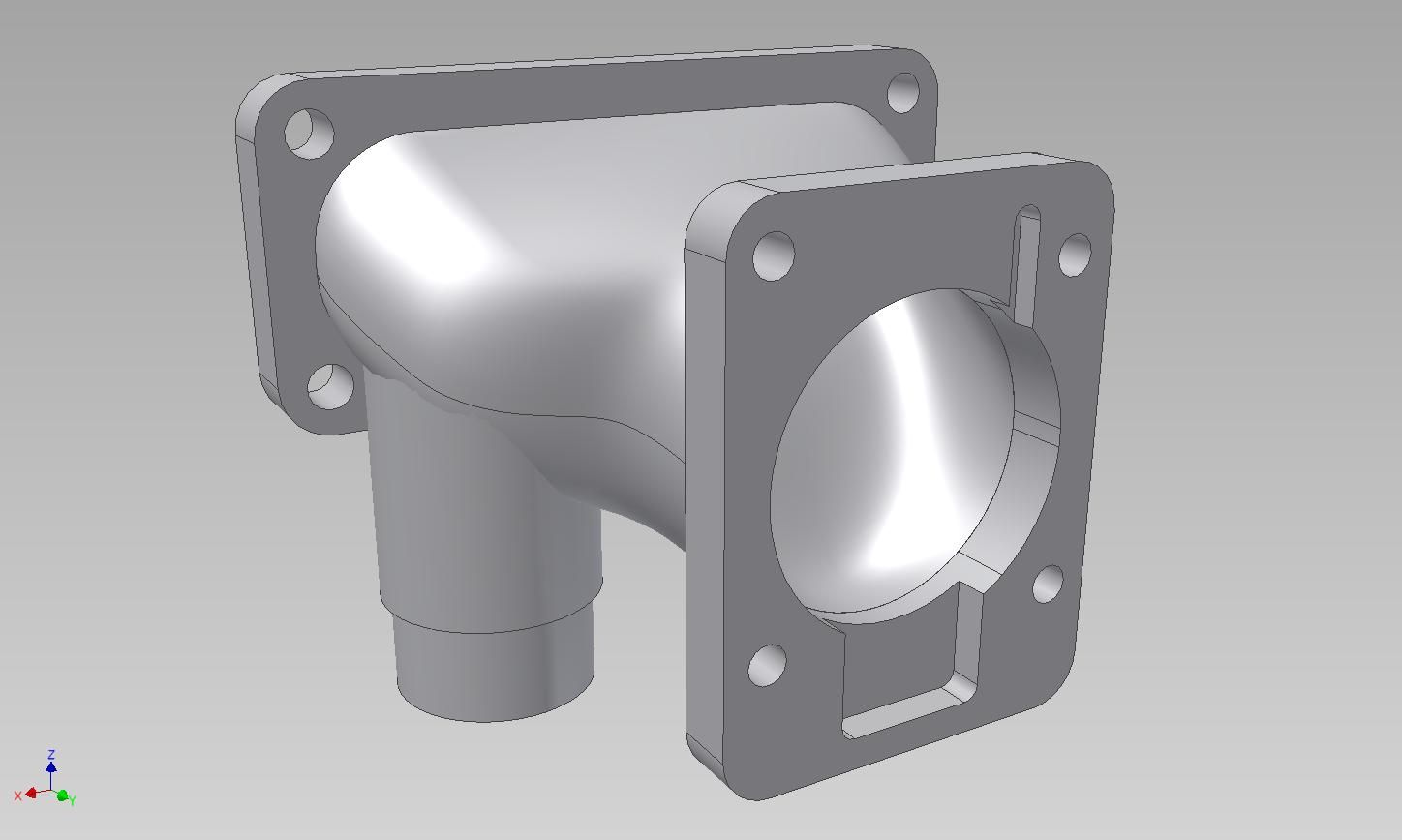

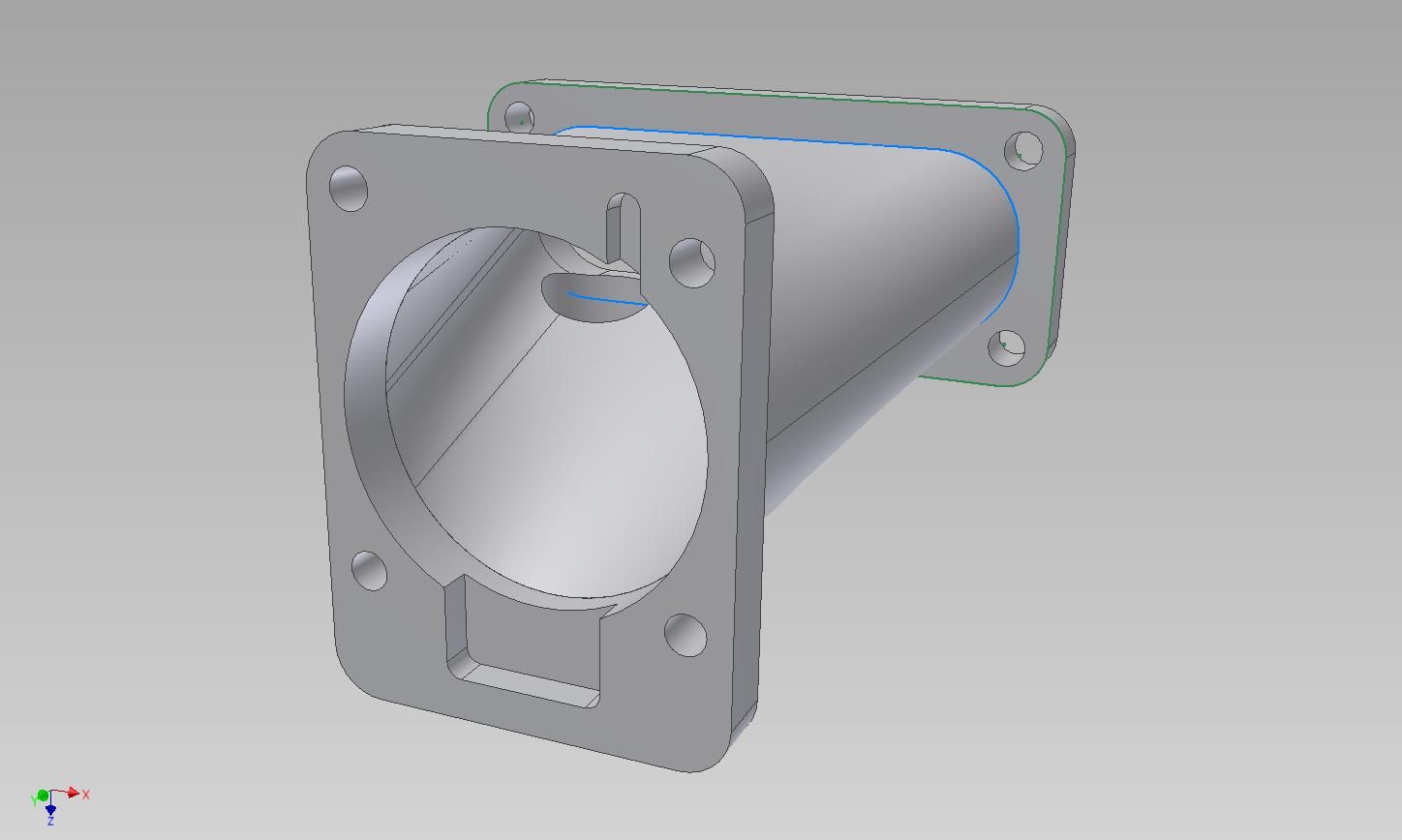

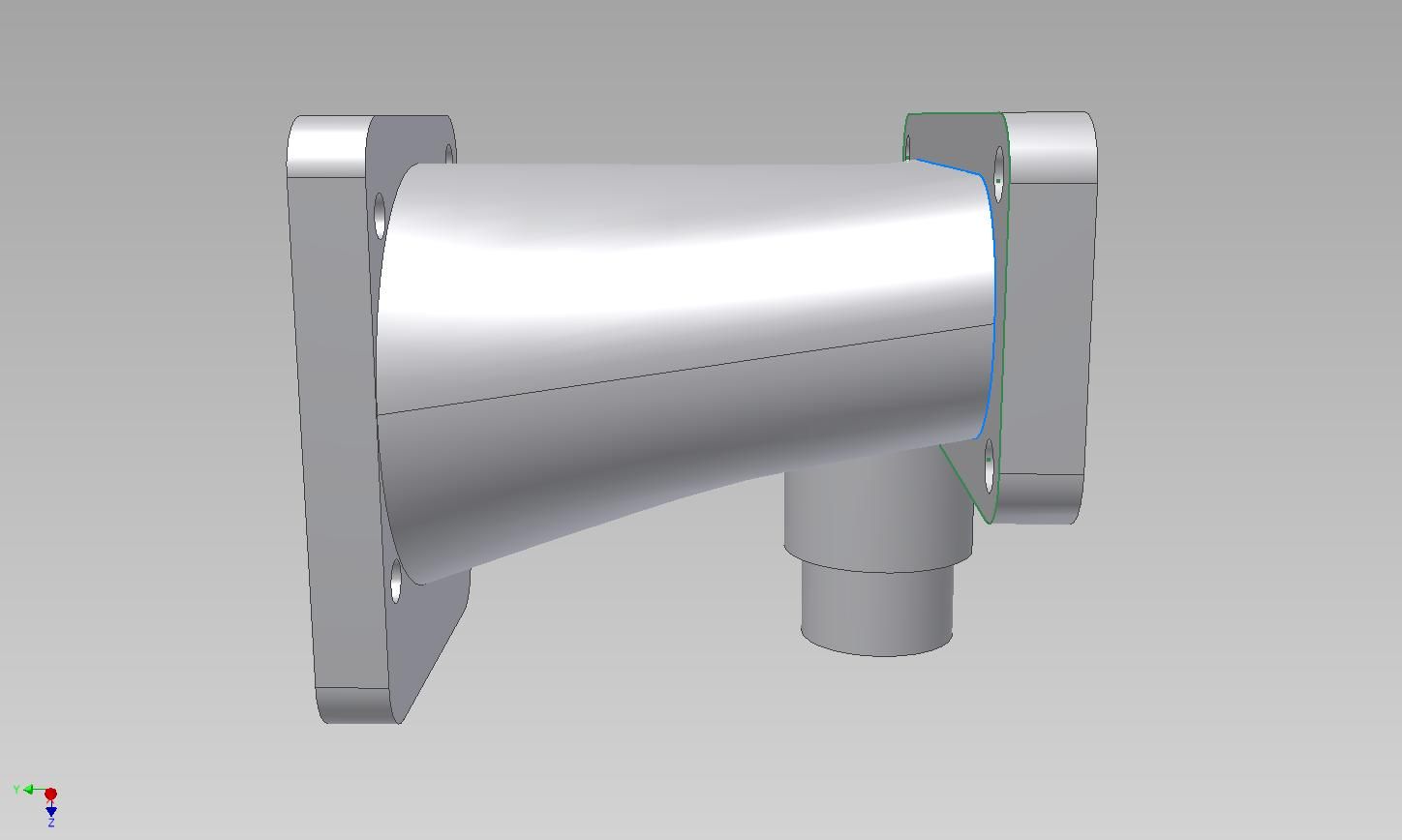

Again I will let the pictures do the talking:

Posted 05 March 2010 - 01:16 PM

Posted 05 March 2010 - 01:22 PM

Edited by cptkirk, 05 March 2010 - 02:13 PM.

Posted 05 March 2010 - 02:31 PM

Posted 05 March 2010 - 03:55 PM

Good to see how much effort you put into insulation and getting the car watertight. The infill is a good option for me too, it's good to see creative tips on the forum. thnx for sharing.

cheerz

Posted 05 March 2010 - 03:58 PM

Posted 05 March 2010 - 04:02 PM

Nice work Captain!

Loving it:)

From one captain to another

Posted 16 March 2010 - 08:59 AM

Posted 16 March 2010 - 01:04 PM

Posted 16 March 2010 - 01:30 PM

Posted 16 March 2010 - 05:30 PM

Yer starting to wrap things up now, it'll be ready for the nicer weather (frickin better be I hear you say), although its spanking gorgeous outside today.

House cleaning = not my dept, thank god.

When I started the build I had no idea I was going to end up being so *rec of the tum* about everything, some say I have got OCD then I correct them by pointing out it should be CDO if you put the letters in alphabetical order..........ha ha.....

It went from a car to just go fast into a car that goes fast and looks good to boot into an anally obsessed proper fast car that must have all the screws turned horizontal - if you know what I mean.... OK its not that bad but you get the idea.

Really looking forward to putting in some miles in it...................

Posted 16 March 2010 - 08:11 PM

Posted 17 March 2010 - 09:10 AM

Yeah I understand. Which makes me even more surprised as most people become less involved to an extent as a build goes on.

People who do this kind of stuff alot always set out for the best which comes with decades of practice or being in the trade. So to change your mind for the better is a bit of a blessing from where your first thoughts were.

I can relate ive been there and i suppose mine was the same, but inevitably had to involve help from others after a time as this was all way over my head.

Can you take credit for alot of the work?! I cant, but I saw the whole things through and made sure I had a hand in everything we did and made every bit my own idea.

In my opinion as you don't see any top fast/race cars out there without the most exceptional presentation and care so your totally correct. But lets hope you never have to take your mini apart in a hurry!

blimey, aint you finished that car yet!!

looking good!!

have you got your sights set on any track dates yet to unleash the beast!

Edited by cptkirk, 17 March 2010 - 09:12 AM.

Posted 17 March 2010 - 12:45 PM

Posted 17 March 2010 - 11:31 PM

Edited by crispy, 17 March 2010 - 11:32 PM.

Posted 18 March 2010 - 12:58 AM

0 members, 2 guests, 0 anonymous users