Edited by cptkirk, 02 December 2009 - 08:31 AM.

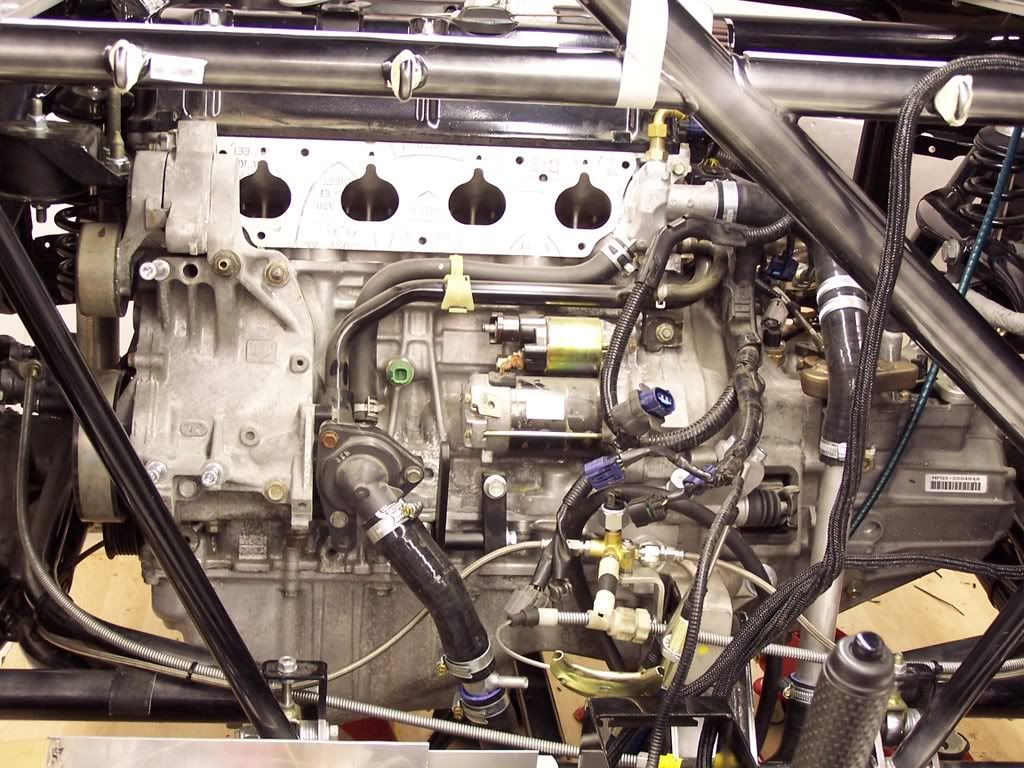

Supercharged K20a2 Vtec - Race Spec

#316

Posted 04 November 2009 - 07:56 AM

#317

Posted 14 December 2009 - 07:45 PM

An amazing build!

Cant wait to see it finished.

#318

Posted 14 December 2009 - 08:59 PM

When I took the car to have it tuned I asked the guy to take a look over the car and advise of anything he saw that I might have done wrong or that were problematic or could prove to be problematic in the future. This has led me to to require a new diff for the car along with considerable reworking of the coolant piping and a few other bits. So its fair to say that I have recently hit rock bottom with the project, not only has the money run out but the weather is rubbish and the thought of running a cable round to my little cold garage isnt floating my boat right now.

However in the midst of all this woe I can see the light and will start to hit it again over christmas as i have some time off. Then January will see me hitting both the wagon and the car.

So over the last month or so I have had a Quaife ATB installed in the car, which wasnt cheap as for some reason the Gripper diff in the car had 10mm bolts in it but Honda use 11mm so I had to pay to have the holes in the final drive ring gear made 1mm bigger at £12 +vat per hole by spark eroding, plus new bearings, plus new bolts for the ring gear. I have to praise Guy at CPL Racing for his help and advice through this change and he only charged 2 hours labour as I dropped the box off to him.

You may be asking yourself why I had to change the diff - the Hondata ECU I am using relies on the use of the speedo pickup for some of its stratigies, like locking out reverse and allowing the vtec to work. So the Gripper diff didnt have a speedo ring gear, and after speaking to Chris at Z's I was told it didnt have the facility for the speedo ring gear.

So I spent the best part of a fortnight on the internet researching the different diff types out there for the K20. There quite a few and I was very close to buying a Wavetrac Diff as they seem to have overcome the only downside to the Torsen type diff (the Quaife is a Torsen type diff), the downside being that when one wheel lifts the diff will react like an open diff. If you want to read up on it heres the link: Quaife ATB.

The diff that I used was not the normal diff used for the Civic Type R, it is the diff specifically designed for the Ariel Atom, the helical gears in the diff are cut at 23deg not 31deg as normal. This makes the diff less agressive and ultimately much better for a lightweight, mid engined, high powered vehicle. I know and knew before I purchased it that it has the downfall of the losing dive if one wheel is off the ground but its major selling point to me was that its biasing is progressive (not like a clutch type LSD which is either on or off), this will make the car far easier to drive in day to day situations, OK it might let me down on a super tight corner on a track but as its not an out and out racer I am arsed......

Another consideration is that the Quaife is a fit and forget, not requiring any maintenance, unlike clutch types..

Another niggle that was brought up was that where I had mounted the temperature sensor for the coolant system was not ideal (I had mounted it on the outlet from the radiator), so again on advice I need to get it as close to the block as possible. The second problem with the coolant was that it wasnt pumping fluid to the radiator under 3000rpm, not helped by the heater matrix bypass pipe that I had purchased a few months before, so I hatched a plan to kill two birds with one stone.

I decided to make a bung/temp sensor adaptor to fit in the block where the outlet for the heater matrix was. This would involve me getting a blank for the heater matrix pipe that goes to the thermostat, some solid brass hex bar and an M20x1.0 Die, the 1/8NPT tap for the temp sensor I already had. I ordered the Die off fleabay on the 2nd Nov and only received it last week, the first brass bar that I ordered got lsot in the post, leading me to get a refund and having to order some more at nearly twice the price, this time it did turn up. Last week the prevous bar ordered in early October turned up as well, the only bonus of the last few months.

So I now need to make the part and install it. My only reservation is it proximity to the eggsauce, although I will make a shield for the outer housing of the sensor. The sensor itself will be well and truly in the flow of the coolant fuild so although it might show a slightly warmer temp than normal it should still be more accurate at showing the engine temps than near the radiator. As a safeguard to over heating I have three linked switches for the fans, one being the radiator switch, one being ECU and another being the external output from the SPA gauge, which can be set to whatever temp you want and can be easily turned on or off, so you can have an over-ride facility allowing constant fan if necessary.

So as you can see its been a testing time recently, not helped by lack of funds.

On the bright side only 7 more days until the days start getting longer..............

Edited by cptkirk, 14 December 2009 - 09:20 PM.

#319

Posted 14 December 2009 - 09:14 PM

For info I ordered the 75A (track) version, 75A being the hardness of the rubber (for those that didnt know) and I only ordered the front and rear mounts as a different side mount is used on the Zcars kit. Approx £230 for the two inc P&P.

I got stung for VAT and a £16 handling charge from the robbing gits at Parcelforce.....If possible when ordering stuff from over the pond dont use USPS as everything they send comes via parcelforce, happened a couple times now.

Edited by cptkirk, 14 December 2009 - 09:16 PM.

#320

Posted 14 December 2009 - 09:27 PM

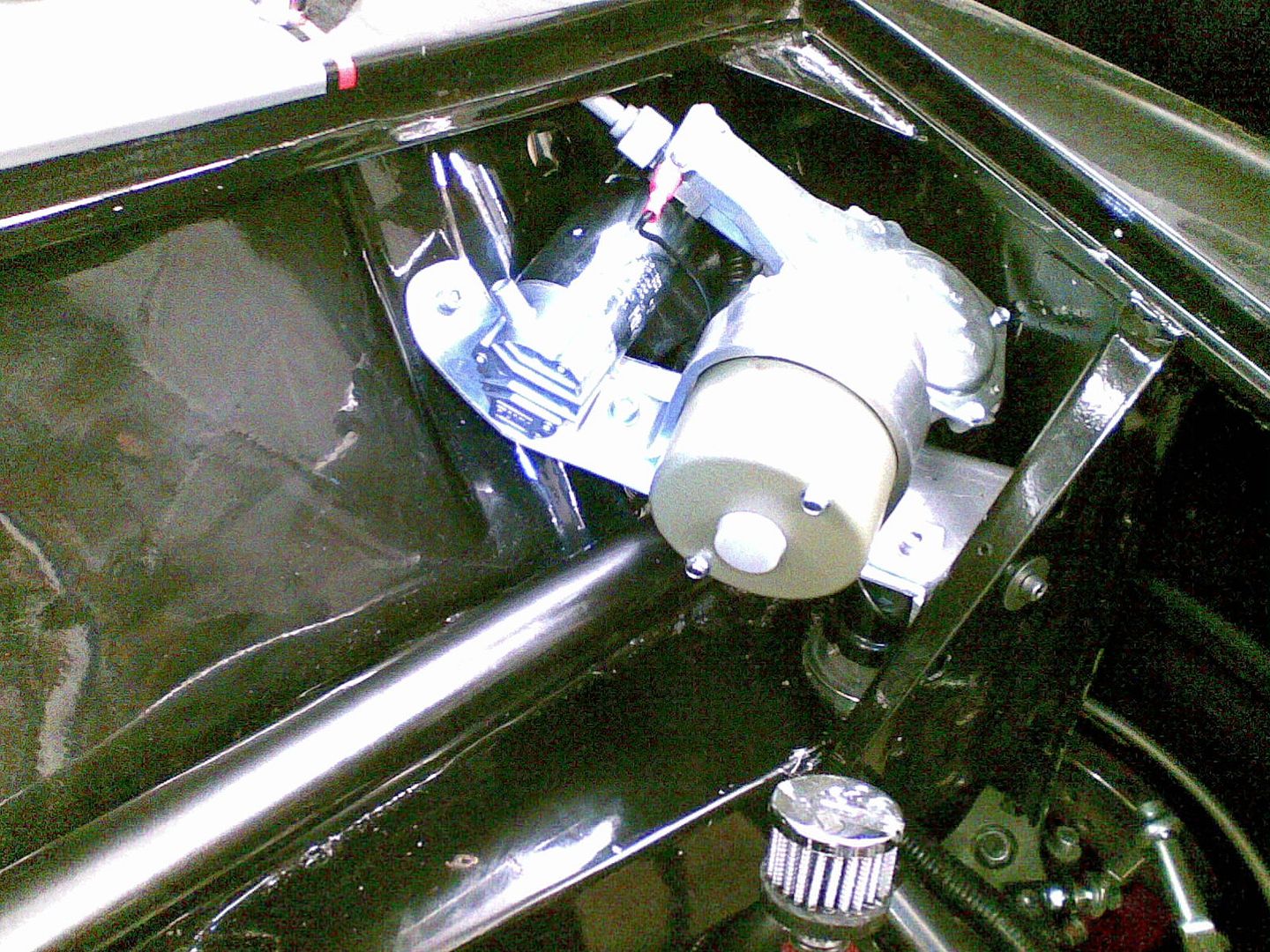

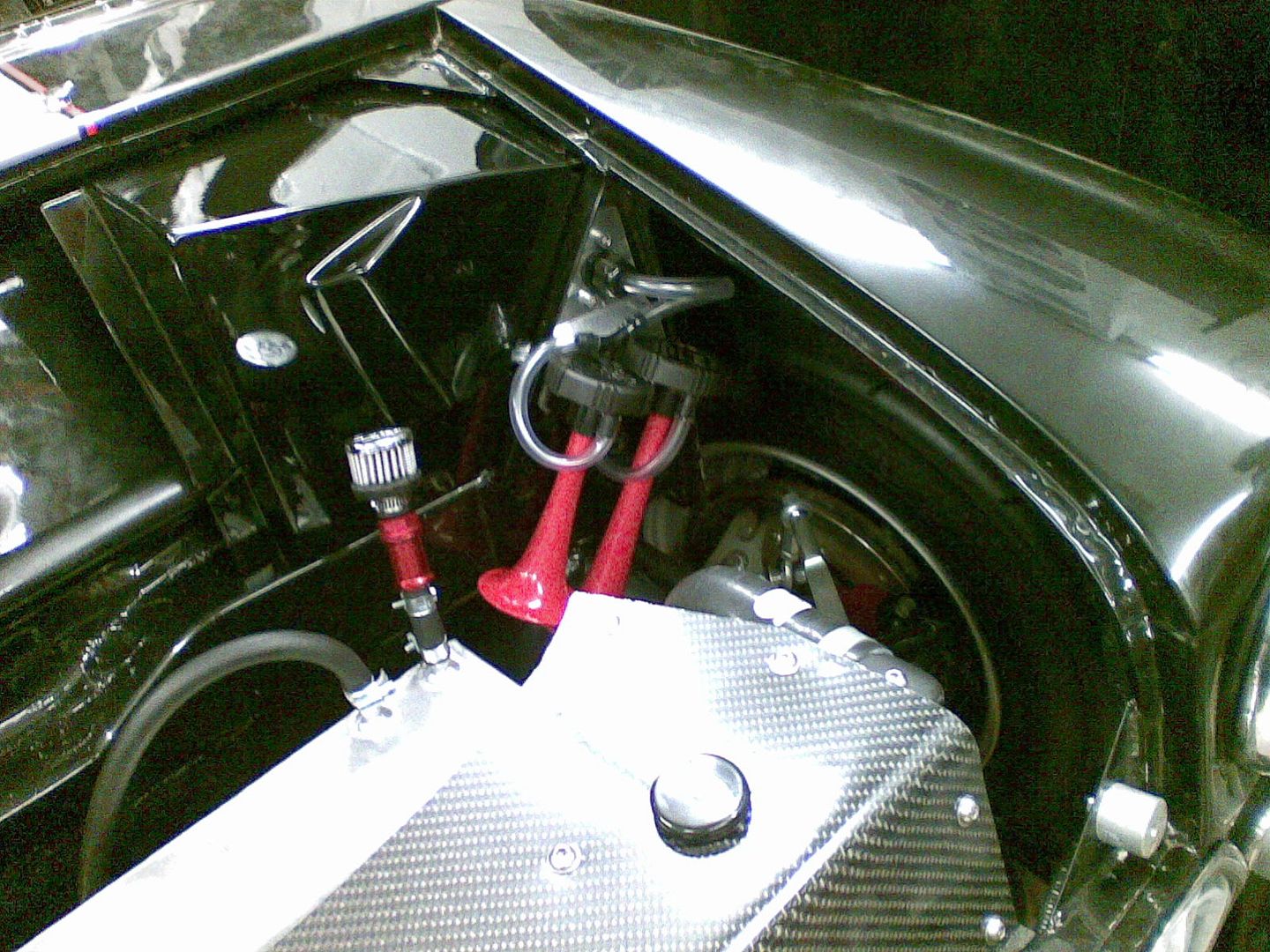

compressor mounted behind washer motor.

piping fed through another gland - handy things those glands....

with the cover in place - neat eh?

#321

Posted 14 December 2009 - 09:32 PM

#322

Posted 16 December 2009 - 03:47 AM

I have a few cars that are toys, Cobra race car, Mini and Turbo Falcon - and they are all great fun to tinker with, change and build up. I think the patience to do such a big project as this car is awesome, probably not for me as i like to smaller projects that have immediate pay back, I would have been driving down the road in a half finished car about a year ago (in fact my Mini is a work in progress that I drive to work each day).

I think comments like - "I might go and get that Vtec" although are enthusiastic do not pay the respect to just how many hours of work have gone into this car. This is the sort of car we all see at shows and race meetings and people have a glance and see new things to look at, but probably dont understand how much work there is.

PS -thanks for the effort on documenting the build, gives the rest of something to read an enjoy as well.

Best of luck with the rest of the project - I will keep an eye on your progress.

#323

Posted 16 December 2009 - 08:51 AM

I have just finished making my way through your project, over the space of two days. Your car is an awesome little machine, will be interesting to see it in action. I bet you are itching to get out and have a drive.

I have a few cars that are toys, Cobra race car, Mini and Turbo Falcon - and they are all great fun to tinker with, change and build up. I think the patience to do such a big project as this car is awesome, probably not for me as i like to smaller projects that have immediate pay back, I would have been driving down the road in a half finished car about a year ago (in fact my Mini is a work in progress that I drive to work each day).

I think comments like - "I might go and get that Vtec" although are enthusiastic do not pay the respect to just how many hours of work have gone into this car. This is the sort of car we all see at shows and race meetings and people have a glance and see new things to look at, but probably dont understand how much work there is.

PS -thanks for the effort on documenting the build, gives the rest of something to read an enjoy as well.

Best of luck with the rest of the project - I will keep an eye on your progress.

Thanks.

The temptation to stick a seat in it and go for a blast has been very great at times, even recently after having the engine tuned I was going to just slap the doors on and take it to a track for a blast round but knowing that I had to swap the diff out made me see sense.

I can hand on heart say that I did not expect it to take this long but I have had a countless amount of setbacks along the way, the majority have not been of my making.

For anyone thinking of doing one of these consider that it isnt like a Caterham where you get every last nut and bolt and a nice instruction manual (I also apreciate that other kits dont) - Oh no, there is virtually diddly squat in the way of how to put one of these together (although Z's are alway happy to talk you through anything) and be prepared to fettle almost everything to make it fit, not just a little fettle but great big ones and maybe even the need to add metal during a fettle (I am poet and I dont know it).

However with all that said when I get to the end of this project I should have a much greater sense of acheivement than your basic kit car in a box person and I will have achieved what I set out to build - A one of a kind mini that will ruin most other cars on the road.

Others that have been down this road will probably agree with the following sentence;

During the build process the car has evolved into something far greater than I ever expected it to be.

I am not going to give up on it now, I am waaaaaaaay too far down the line for that, in fact writing this is giving me renewed vigour to get my sorry ass out in the garage and get tinkering.

Edited by cptkirk, 16 December 2009 - 08:54 AM.

#324

Posted 16 December 2009 - 09:22 AM

There's nothing more that need to be said.

#325

Posted 16 December 2009 - 09:12 PM

#326

Posted 18 December 2009 - 08:01 PM

#327

Posted 23 December 2009 - 04:00 PM

#328

Posted 23 December 2009 - 11:47 PM

We have 2 type R's as our daily cars & 1 is N/A & the other is SC so im liking this thread as it combines the CTR SC & Mini

#329

Posted 26 January 2010 - 07:21 PM

HALLELUJA!!!

There's nothing more that need to be said.

Like it.....

hows the diff? the gripper is well harsh on normal driving especially pulling away on lock, its the only thing that lets it down, interested in how you get on with it......like the air horns! they'll confuse the harbour master!

Unsure yet - still not had a run out yet - still fettling

My God this car is nice. I want to see some driving videos!

Me too.....

been in this site for years now and seen many projects before. but never seen a project with such a level of attention to the details. so carry on the great work we are looking forward for a great driving vid from u. take time dont rush things up, as this far the project looks really neat

Thanks, cant wait to make a driving vid.....

I am following this with alot of interest as this is what i am planning to do to my Mini

We have 2 type R's as our daily cars & 1 is N/A & the other is SC so im liking this thread as it combines the CTR SC & Mini

I miss my old ATR, wish I could have kept hold of it til this was finished but just didnt have the funds so daily driver is an 04 plate Accord CDTI, bit of a barge but it'll do for getting me to work. If your thinking of doing one take heed of what Cobra V8 posted earlier - it aint a walk in the park - but it is rewarding.

#330

Posted 26 January 2010 - 07:56 PM

Not out there tonight as its a bit too cold for me so I thought I would share my plans and some fo the stuff I have been up to.

First thing was I made another list of stuff to do, which keeps growing each time I go out to the garage but I am finding it the best way to deal with it, pick a thing that needs doing, knowing how much time you have and get it done - simples....

So in one of my prevoius threads I was talking about making a bung/temp sensor holder, well I decided against that idea and have now decided to go with just a stright blanking plug/bung for the old heater matirx output from the block. I have also decided (last night) that I need to take the supercharger and manifold off one more time so that I can get to the solid coolant pipe that runs from the thermostat to where it would have been connected to the heater matrix, pretty much right next to the bung I was just going on about. In the photo below you can see the solid pipe I am going on about. Note the flexi hose that follows that up and more importantly the housing at the top of the pipe.

So I decided to put my water temp sensor right into this housing. I had made the decision some time ago that I wasnt going to run the pre-warm coolant pipes to the throttle body as I wasnt going to be driving it in conditions that would warrant it and I will always take the time to thoroughly warm the engine before taking it out. Also there will be much more heat coming back towards the throttle body from the supercharger than with a N/A engine.

I drilled out the lower 8mm steel pipes from the housing and tonight I popped into my mate Stevie G's as I had given him my 1/8" NPT tap to make my previously mentioned bung/sensor holder with (now just a bung - as above), we tapped that bad boy out and here it is - excuse fingers:

And here are a couple more shots - pretty poor quality though......

A got a couple of shots of my new engine mounts - I plan to get them in once I can get to back up to Crazy Mikes and abuse one of his his two poster ramps - seen previously when I took the engine out. Anyhow enough blah - here are the mounts (dont get too excited):

Yer I know there not the billet ones but it was what I could afford................

So the plan from here - get these coolant system bits nailed, finish off the few electrical bits I have yet to do, still a few bodywork (under bonnet) bits to do, doors need hanging, carpeting, in fact I already have a list why the feck am I repeating it all here, its safe to say that I still have a couple of months of work ahead of me to get it ready for a shakedown, my problem is I want everything to be just right before I take it out for a spin. I realise I will have to go over it again with the spanners to make sure all is tight but I dont want to go half hearted into driving it or things jsut wont get finished, even though I realise it will probaly never truly be finished as I already have plans developing in my head for intercoolers and other stuff

I knows its been a long road but I remember when it used to look like this back in May '08, its come along way since then:

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users