Supercharged K20a2 Vtec - Race Spec

#136

Posted 26 May 2009 - 06:24 PM

#137

Posted 26 May 2009 - 08:55 PM

Nice diffuser! I hope to be fitting mine from Carbon Weezel in the next week or two.

I looked at those but couldnt justify the money and I had this little voice in my head saying "I am sure you could make one of those" so in at the deep end I went and by the time I have finished I should have just bought one from the Carbon Wheezel - ha ha - never mind, its been a good learning experience.

My next thread will interest you.

#138

Posted 26 May 2009 - 09:02 PM

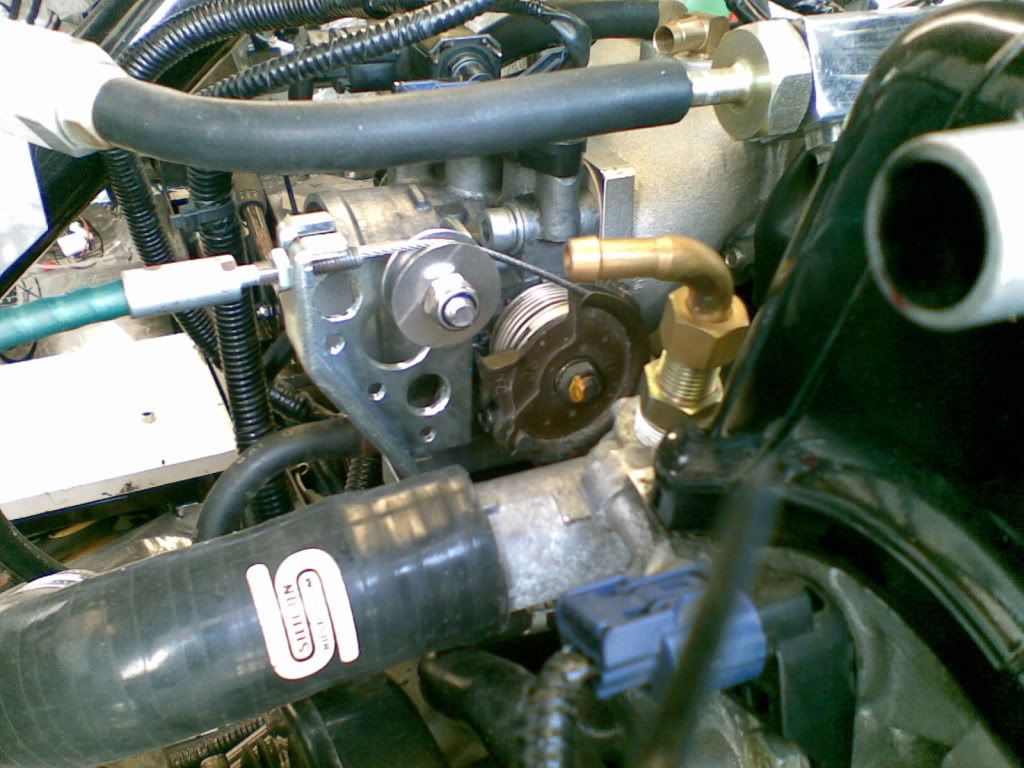

I had to make a slight alteration to the throttle mount to get it working sweet, my original calcs were a bit off. Anyhow - adapt and overcome......

I made use of a skateboard wheel bearing, an 8mm bolt, one standard 8mm nut, one nylock 8mm nut and two penny washers, the result is what you see below, even if I do say so myself it runs sweeeeet now..........:

#139

Posted 26 May 2009 - 09:06 PM

So yesterday I finished off the diffuser plug, primed it and took it my friend Stuart, who's going to whip a mould off it and then make my diffuser.

The next and rather more difficult part will be making the joining peice between the lip below the boot and the diffuser.

Anyhow - here are a couple of shots of the diffuser just before it went in the van:

#140

Posted 26 May 2009 - 09:18 PM

After cleaning the spray paint off of my van and my garage door that some little chav had kindly put on there ( i dont mid the garage doors that much but do not under any circumstances f*ck with a mans vehicle, I hope Karma gives the kid Hemeroids for life) I went about making progress on the car.

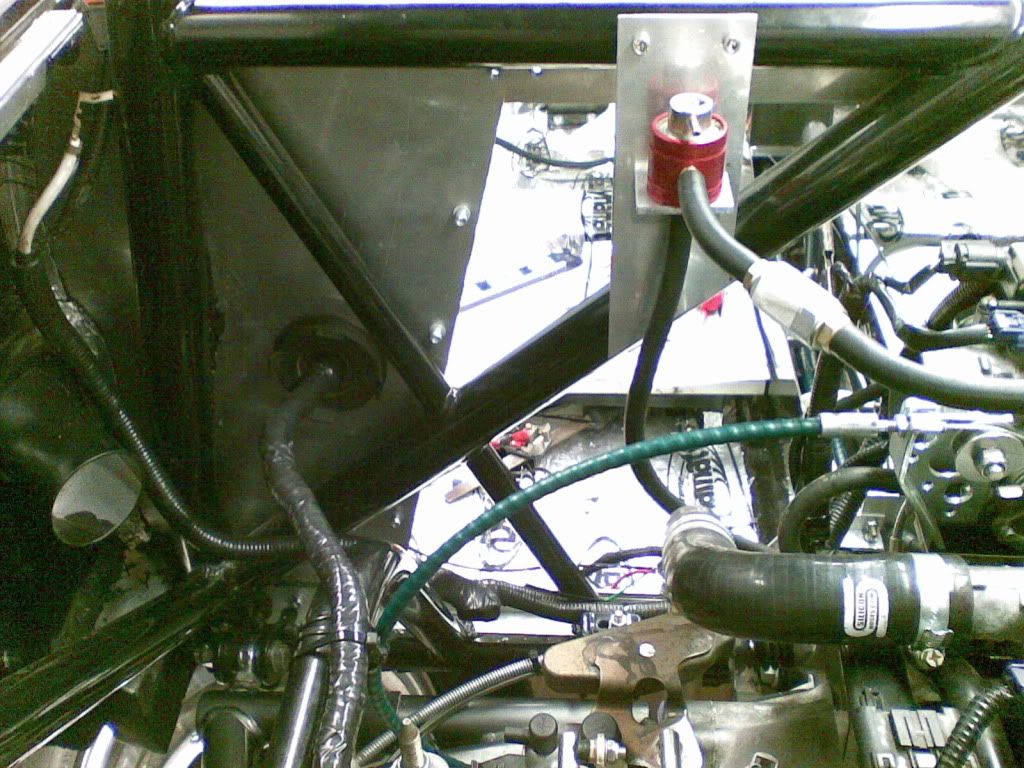

I spliced in the new connectors for the injectors tonight, fiddly little buggers but I got there in the end.

Re-stuck the roof lining to the roof, original sticking was not up to the job and had sagged (not of my doing), so some industrial strength double sided sticky tape and the misses giving me a hand and we had it stuck up in no time, and the roof lining....way heeeey.........

No pictures in this one......boooo.....

#141

Posted 27 May 2009 - 03:52 PM

#142

Posted 27 May 2009 - 07:58 PM

why did a lil f*k do that to your van and door?!

You are far too polite

Sorry to hear about the van.. Karma has a great way of coming back to people..

#143

Posted 27 May 2009 - 08:35 PM

why did a lil f*k do that to your van and door?!

You are far too polite

Sorry to hear about the van.. Karma has a great way of coming back to people..

Victim of circumstance, just kids being kids, or rather more kids being little A-holes, the vans parked right next to a garage with no door where the chavs hangout to smoke and drink and I just happen to have nice galvanised doors on my garage which just cry out to be sprayed up if your that way inclined. I was no angel when I was a teenager but I never sprayed up someones car or van. Anyhow whats done is done and its all cleaned off, they will get there dues.....

#144

Posted 27 May 2009 - 09:11 PM

They are made by Selective Laser Sintering and are made from Nylon so are strong enough to use as body part. They will be off to be sprayed by my mate Stuart to match the bodywork.

I sent them a 3D model in an STL file and they sent me the parts in the post - doesnt get much easier than that.

Laserproto.com if anyone is interested.

Another "SAW IT HERE FIRST" moment:

#145

Posted 27 May 2009 - 09:13 PM

#146

Posted 27 May 2009 - 09:21 PM

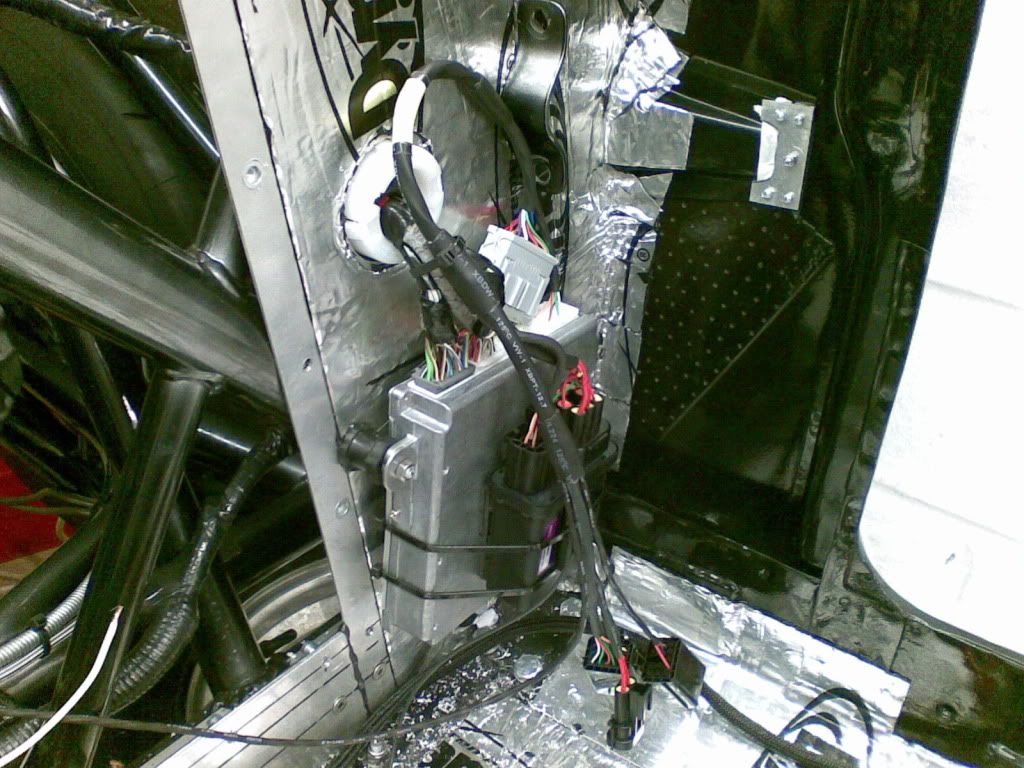

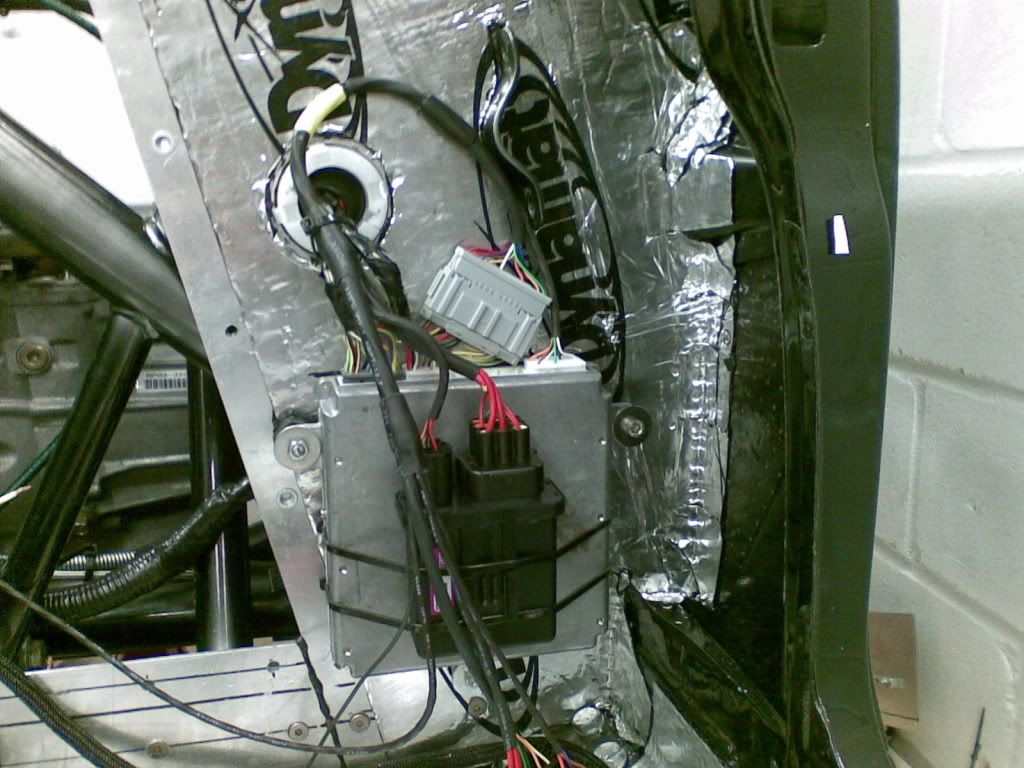

Now do I feel I can do the wiring or do I get someone in to do it???

#147

Posted 28 May 2009 - 01:06 AM

I got a delivery today - my Scoop Fixing Plates

They are made by Selective Laser Sintering and are made from Nylon so are strong enough to use as body part. They will be off to be sprayed by my mate Stuart to match the bodywork.

I sent them a 3D model in an STL file and they sent me the parts in the post - doesnt get much easier than that.

Laserproto.com if anyone is interested.

Another "SAW IT HERE FIRST" moment:

Sweet.. SLS is the business

Extremely impressed!! Great use of technology!!

Edited by irishdude, 28 May 2009 - 01:06 AM.

#148

Posted 28 May 2009 - 09:10 AM

Is there any reason why you used SLS though? Are there some features on the plates that would have been more expensive to machine or was it just becasue you could?

#149

Posted 28 May 2009 - 02:48 PM

#150

Posted 28 May 2009 - 04:05 PM

I am guessing PEEK is stronger than Nylon? I dont have a Masters in Engineering so I dont know, advice welcomed on that subject.

I had previously had the outline Laser cut from 6mm plate and planned to mill it al out but the steel plates came in a 630g each and the Nylon is 56g each so a no brainer on the weight front. Also the Bolts going through the plate is what is taking the stress, not the plate so all good there. I could have designed a plate that incorporated its own 'ear', but I decided to go with what I had. You never know someone else might want some. will have to work a cheaper way to get them made.

Thanks for the comments, there's still more to come, its all in the Work In Progress file at the moment.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users