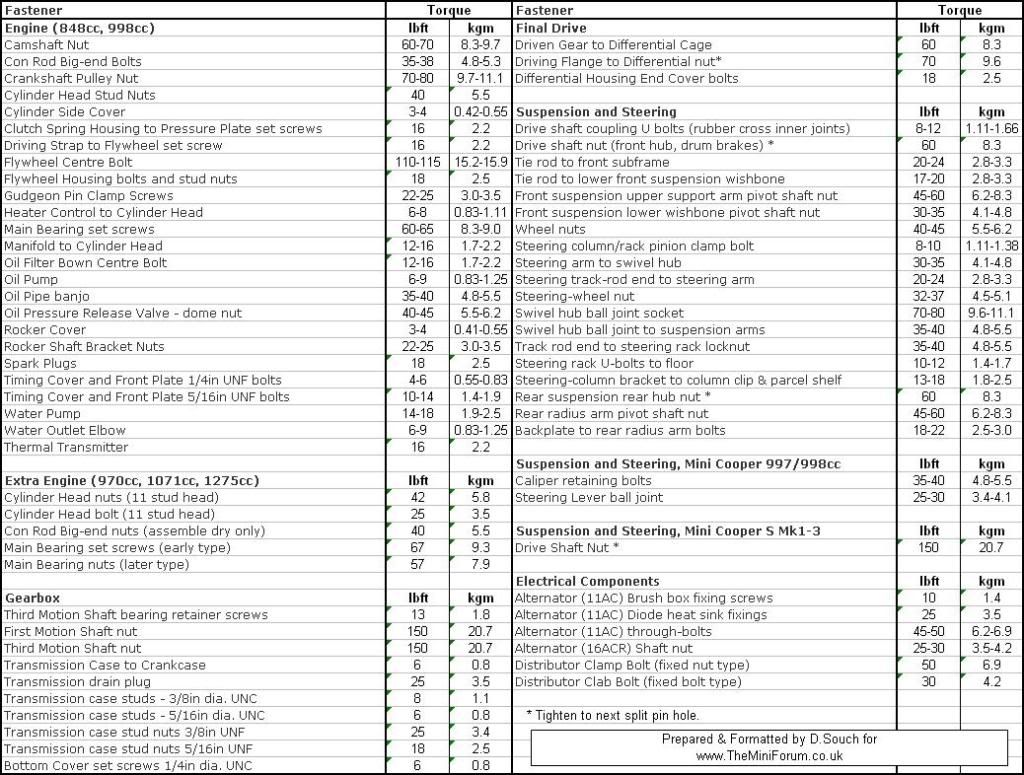

Fastener Torque (lbft) Torque (kgm)

Drive shaft coupling U bolts (rubber cross inner joints) 8 to 12 1.11 to 1.66

Drive shaft nut (front hub, drum brakes). Continue tightening until next split pin slot aligns. Do not slacken off until the next slot aligns! 60 8.3

Tie rod to front subframe 20 to 24 2.8 to 3.3

Tie rod to lower front suspension wishbone 17 to 20 2.8 to 3.3

Front suspension upper support arm pivot shaft nut 45 to 60 6.2 to 8.3

Front suspension lower wishbone pivot shaft nut 30 to 35 4.1 to 4.8

Wheel nuts 40 to 45 5.5 to 6.2

Steering column/rack pinion clamp bolt 8 to 10 1.11 to 1.38

Steering arm to swivel hub 30 to 35 4.1 to 4.8

Steering track-rod end to steering arm 20 to 24 2.8 to 3.3

Steering-wheel nut 32 to 37 4.5 to 5.1

Swivel hub ball joint socket 70 to 80 9.6 to 11.1

Swivel hub ball joint to suspension arms 35 to 40 4.8 to 5.5

Track rod end to steering rack locknut 35 to 40 4.8 to 5.5

Steering rack U-bolts to floor 10 to 12 1.4 to 1.7

Steering-column clip bracket to cloumn clip and parcel shelf 13 to 18 1.8 to 2.5

Rear suspension rear hub nut. Continue tightening until next split pin slot aligns. Do not slacken off until the next slot aligns! 60 8.3

Rear radius arm pivot shaft nut 45 to 60 6.2 to 8.3

Backplate to rear radius arm bolts 18 to 22 2.5 to 3.0

Suspension and Steering, Mini Cooper 997/998cc

Fastener Torque (lbft) Torque (kgm)

Caliper retaining bolts 35 to 40 4.8 to 5.5

Steering Lever ball joint 25 to 30 3.4 to 4.1

Suspension and Steering, Mini Cooper S Mk1-3

Fastener Torque (lbft) Torque (kgm)

Drive Shaft Nut. Continue tightening until next split pin slot aligns. Do not slacken off until the next slot aligns! 150 20.7

Electrical Components

Fastener Torque (lbin) Torque (kgm)

Alternator (11AC) Brush box fixing screws 10 0.115

Alternator (11AC) Diode heat sink fixings 25 0.288

Alternator (11AC) through-bolts 45 to 50 0.518 to 0.576

Alternator (16ACR) Shaft nut 25 to 30 3.5 to 4.2

Distributor Clamp Bolt (fixed nut type) 50 0.576

Distributor Clab Bolt (fixed bolt type) 30 0.345

Engine (848cc, 998cc)

Fastener Torque (lbft) Torque (kgm)

Camshaft Nut 60 to 70 8.3 to 9.7

Con Rod Big-end Bolts 35 to 38 4.8 to 5.3

Crankshaft Pulley Nut 70 to 80 9.7 to 11.1

Cylinder Head Stud Nuts 40 5.5

Cylinder Side Cover 3 to 4 0.42 to 0.55

Clutch Spring Housing to Pressure Plate set screws 16 2.2

Driving Strap to Flywheel set screw 16 2.2

Flywheel Centre Bolt 110 to 115 15.2 to 15.9

Flywheel Housing bolts and stud nuts 18 2.5

Gudgeon Pin Clamp Screws 22 to 25 3.0 to 3.5

Heater Control to Cylinder Head 6 to 8 0.83 to 1.11

Main Bearing set screws 60 to 65 8.3 to 9.0

Manifold to Cylinder Head 12 to 16 1.7 to 2.2

Oil Filter Bown Centre Bolt 12 to 16 1.7 to 2.2

Oil Pump 6 to 9 0.83 to 1.25

Oil Pipe banjo 35 to 40 4.8 to 5.5

Oil Pressure Release Valve - dome nut 40 to 45 5.5 to 6.2

Rocker Cover 3 to 4 0.41 to 0.55

Rocker Shaft Bracket Nuts 22 to 25 3.0 to 3.5

Spark Plugs 18 2.5

Timing Cover and Front Plate 1/4in UNF bolts 4 to 6 0.55 to 0.83

Timing Cover and Front Plate 5/16in UNF bolts 10 to 14 1.4 to 1.9

Water Pump 14 to 18 1.9 to 2.5

Water Outlet Elbow 6 to 9 0.83 to 1.25

Thermal Transmitter 16 2.2

Engine (970cc, 1071cc, 1275cc)

Use this data in conjuction with the data for Engine (850, 998cc)

Fastener Torque (lbft) Torque (kgm)

Cylinder Head nuts (11 stud head) 42 5.8

Cylinder Head bolt (11 stud head) 25 3.5

Con Rod Big-end nuts (assemble dry only) 40 5.5

Main Bearing set screws (early type) 67 9.3

Main Bearing nuts (later type) 57 7.9

Gearbox

Fastener Torque (lbft) Torque (kgm)

Third Motion Shaft bearing retainer screws 13 1.8

First Motion Shaft nut 150 20.7

Third Motion Shaft nut 150 20.7

Transmission Case to Crankcase 6 0.8

Transmission drain plug 25 3.5

Transmission case studs - 3/8in dia. UNC 8 1.1

Transmission case studs - 5/16in dia. UNC 6 0.8

Transmission case stud nuts 3/8in UNF 25 3.4

Transmission case stud nuts 5/16in UNF 18 2.5

Bottom Cover set screws 1/4in dia. UNC (change-speed tower) 6 0.8

Final Drive

Fastener Torque (lbft) Torque (kgm)

Driven Gear to Differential Cage 60 8.3

Driving Flange to Differential nut (tighten to next split pin hole) 70 9.6

Differential Housing End Cover bolts 18 2.5