How The Gearbox Works

#1

Posted 09 September 2004 - 07:03 AM

can someone explain to me what Synchromesh is

and try and make me understand gear ratios

all help in this matter is much appreciated

#2

Posted 09 September 2004 - 11:35 AM

A synchromesh is a device for making the change into a gear smooth, essentially what it does is matches the speed of the gear to the speed of the output shaft before the gear is engaged. It does this by the use of what is called a baulk rings.

Time for a couple of pictures....

This is a simplified cross section of a Syncromesh ( Blue / Grey ) and a Gear ( Red ). The green section is the baulk ring. The synchro is fixed to the output shaft, whereas the gear is free to rotate on a bearing ( Yellow ).

When you engage a gear ( moving the gear stick ), this moves the selector fork in the box which is contected to the outer (Grey) part of the Synchro. As the lever is moved, the Outer part moves towards the gear taking the baulk ring (Green) with it. You will notice the sloping surfaces on the Gear and the inside of the ring. This is a friction surface. Before the outer part of the synchro meets the gear, the ring and the gear meet, and friction then starts to spin the gear at the same speed as the syncro. When this 'Syncronisation' has been achieved then the outer part of the syncro is 'engaged' with the gear using dog teeth, which match the inside of the syncro.

When this is done then the Synchro and gear are turning as one...

The power from the engine is delivered to this arrangement via the Lay gear, which drives all gears, and hence all gears receive engine power at all times. The synchros determine which one of those gears is then locked to the output shaft and delivers power to the road wheels...

Grinding gears ??, this happens when the gear does not get to the correct speed before the dog teeth are engaged.... hence, forget to press the clutch, the output shaft is going at road speed and the input ( laygear ) is going at engine speed.. which are very unlikely to be the same.... hence grind

If you grind gears when pressing the clutch, and it is not maladjusted, then there is a strong possibility that the baulk ring friction surfaces are worn down and no-longer doing their job.

Try this ( but only once or twice ), when driving in 3rd, get to a steady speed and depress the clutch, and change to neutral, and re-engage clutch (your now coasting). With gentle pressure on the gear stick move it towards 4th, at the same time slowly increasing the engine speed from idle. At a point, the gear will just pop in, this is when the 4th Gear and 3rd/4th Synchro are rotating at the same speed, and thus allowing the dog-teeth to engage.

Edited by GuessWorks, 13 August 2007 - 01:19 PM.

#3

Posted 09 September 2004 - 12:51 PM

First of all lets forget about the drop gears and differential for the moment, as they only affect input and output speed respectively for all gears...

Picture time...

The Upper row of gears (red,green,blue,yellow) is the Laygear, and has associated 1st 2nd and 3rd gears on the output shaft.

4th or 1st motion shaft ( just to confuse matters) is a little special as when this is engaged, essentially the Input and output shaft are directly connected and hence why ALL mini 4th Gears are described as a 1:1 ratio. But what it also does it provides the power transfer to the Lay gear ( which controls the other ratios )...

The standard 4 synchro rod change box (pre A+) has a laygear with 15,20,25 and 29 teeth ( left to right ), 1st gear has 31, 2nd 26 and 3rd 21, the 1st motion shaft has 17... therefore...

using the following the equasion the output ratio can be calculated...

1st motion teeth Leygear teeth for gear ratio = ------------------- * -------------------------- Laygear teeth Gear teeth

hence for 1st....

ratio = 17/29 * 15/31 = 0.284

which means for every one turn of the engine, the gearbox output shaft rotates 0.284 times..

2nd = 0.451

3rd = 0.698

A+ gear boxes have a different laygear, both in shape and ratios... with 15,21,26 and 30 teeth, the gears ( and 1st motion ) stay the same hence...

1st = 17/30 * 15/31 = 0.274

2nd = 0.458

3rd = 0.702

One other thing worthy of note, are Close ratio boxes, an example of which was on the bottom on the 1275 GT... This had the same number of teeth on the Laygear but with a smaller diameter. which ment that the 1st motion could have an extra tooth ( 18 instead of 17 ).... This has the effect of making 1st gear longer and bringing all the gears closer ( hence Close ratio ).....Here cometh the Math...

1st = 18/29 * 15/31 = 0.300

2nd = 0.477

3rd = 0.739

I think in haynes etc, they quote these the other way round, ie engine revolutions required to turn output shaft once, to get this number, divide 1 by the ratio given.

Now you will hear mention of the final drive ratio ( eg 3.7 or 3.44 to 1 ) which is infact the ratio of the Differential, in otherwords the number of times the output of the gearbox goes round for a single revolution of the differential ( road wheels )

Drop gears are the method in whcih power is transferred from the crank to the gearbox, in standard minis this is a 1:1 ratio, however they are available in other ratios, normally only for competition, they only vary very small amounts, but at this stage of power transfer have a great effect on the overall ratio

Phew... I'm pooped now !!

Edited by GuessWorks, 13 August 2007 - 01:20 PM.

#4

Posted 09 September 2004 - 10:03 PM

#5

Posted 09 September 2004 - 10:11 PM

#6

Posted 09 September 2004 - 11:23 PM

Syncros are clutches that allow the gears to change speed top allow a smoth selection of gears.

You really need to find a good book.

Siggy

#7

Posted 23 October 2007 - 08:10 AM

#8

Posted 23 October 2007 - 12:23 PM

#9

Posted 23 October 2007 - 12:30 PM

#10

Posted 25 February 2012 - 05:24 AM

our admin get there in the end

yup they do

#11

Posted 14 May 2012 - 07:28 PM

#12

Posted 18 May 2012 - 05:45 PM

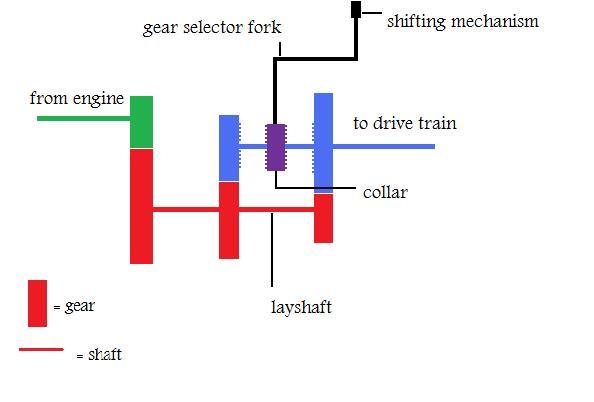

There are more piccies you can find with google. Basically green turns red, then red turns blue and you move purple (the synchro, which slides on splines on the shaft to lock the blue gears to the shaft via itself. Top (4th) has a similar arrangement to lock the green "1st motion" shaft end on to the blue main shaft (also called the 3rd motion shaft)

#13

Posted 27 January 2013 - 11:58 AM

Sorry if this isn't the right place to post a question.

Thanks for any help!

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users