Hello...

Happy new year to all - been a while since I posted anything in the thread... Basically because I didn't have much to report. Was away for a few weeks over Xmas, then other commitments etc in Jan and Feb - but have now picked this again so here's a short update.

We have built high stands to allow good access to the underside of the shell. When it comes time to install the prop, exhaust mountings, rear and front subframes etc this should make it a lot easier. Although I have spent a fair bit of time on the computer working on the design for the car, it was good to get back out in the workshop (now that the weather is getting warmer) and see some tangible progress.

The car up in the air...

Spent this afternoon continuting to clean all the seam sealer and gunk off the bulkhead and underside. I've found progress is better with air drill / cup brush, a wallpaper scraper and a blowlamp than with the shot blastung gun.

The blowlamp also softens the bitumen sound deadening a treat - it comes off like marzipan once you warm the panels....

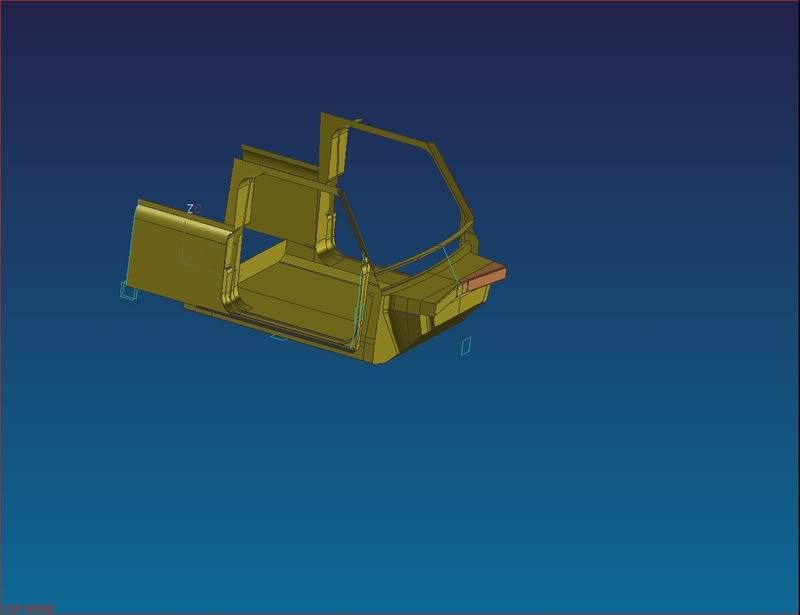

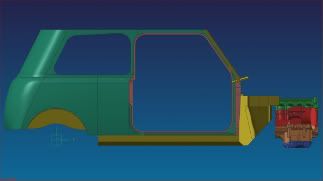

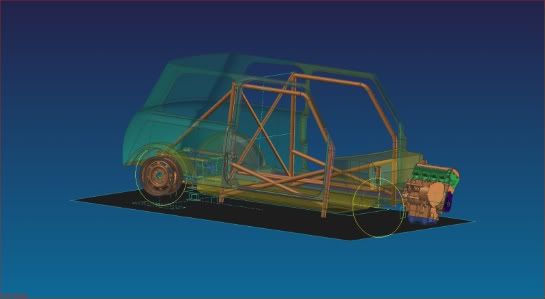

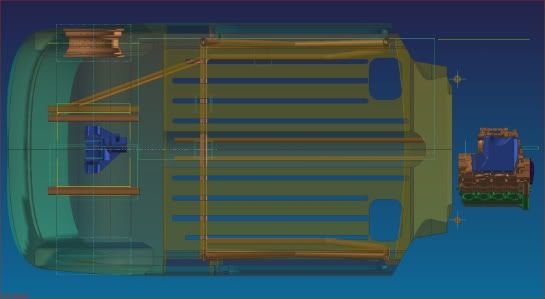

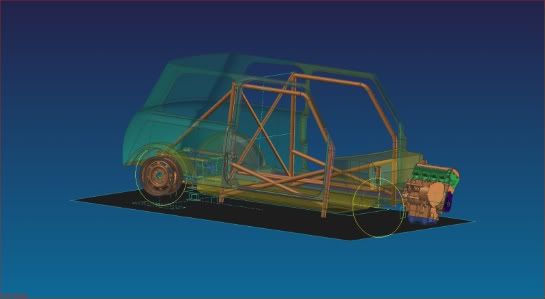

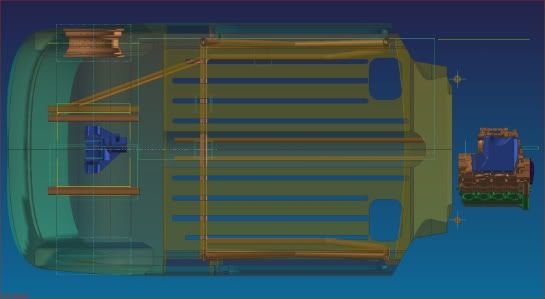

In terms of design progress, I'm still laying the whole thing out really. I've been doing a lot of reading about suspension design, and have a decent idea of what I should be looking to acheive at the back end. I have the diff - and have modelled it - so am well positioned to sort out the back end. Also had an excellent conversation with Bailey Morris (propshaft manufacturers) today, so again am well prepared to lay this all out. I am thinking that there are several reasons to end up with a left hand drive car at the end of it, as this would allow me to move the prop pver to the right of the car a little without compromising driver's postion too much. There's erm.. lets call it "a good reason"... to leave maximum space on the exhaust side of the engine as well - an area which is compromised package wise if you have a central running propshaft.

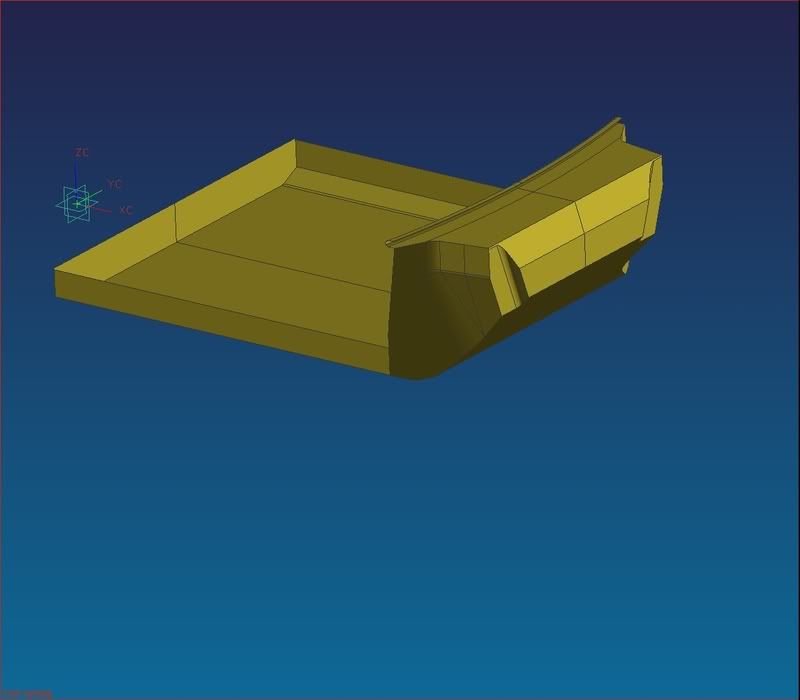

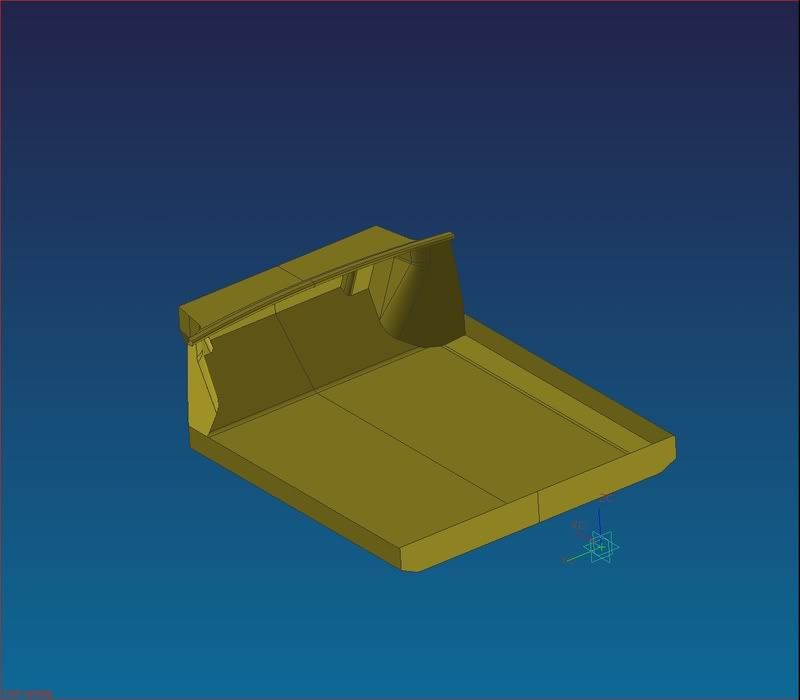

Anyway - here's a couple of screenshots....

David.