Oil Gallery Plugs

#1

Posted 20 June 2016 - 08:01 PM

I have a 1275cc a+ which has just been to the machine shop but hasn't had the oil gallery plugs replaced. I am therefore looking for a how to step by step or simply some tips so I don't ruin the money I have just parted with on the block!!

Thanks for any guidance!

Andy

#2

Posted 20 June 2016 - 08:25 PM

For standard engine rebuild with block having known history you shouldn't really need to replace the oil gallery plugs..

However if the engine or gearbox has had a major malfunction then taking gallery plugs out and cleaning right through would be advisable, in case of any debris getting past the oil filter.

#3

Posted 20 June 2016 - 08:43 PM

For the price of them, replace them.

Whilst they're out you can get in there with some compressed air, clutch cleaner and pipe cleaners to remove any dirt and debris

#5

Posted 21 June 2016 - 07:48 AM

I always pull the Main Oil Gallery plugs as a minimum in any engine build. I do think you can properly clean and then inspect all the Oil ways any other way.

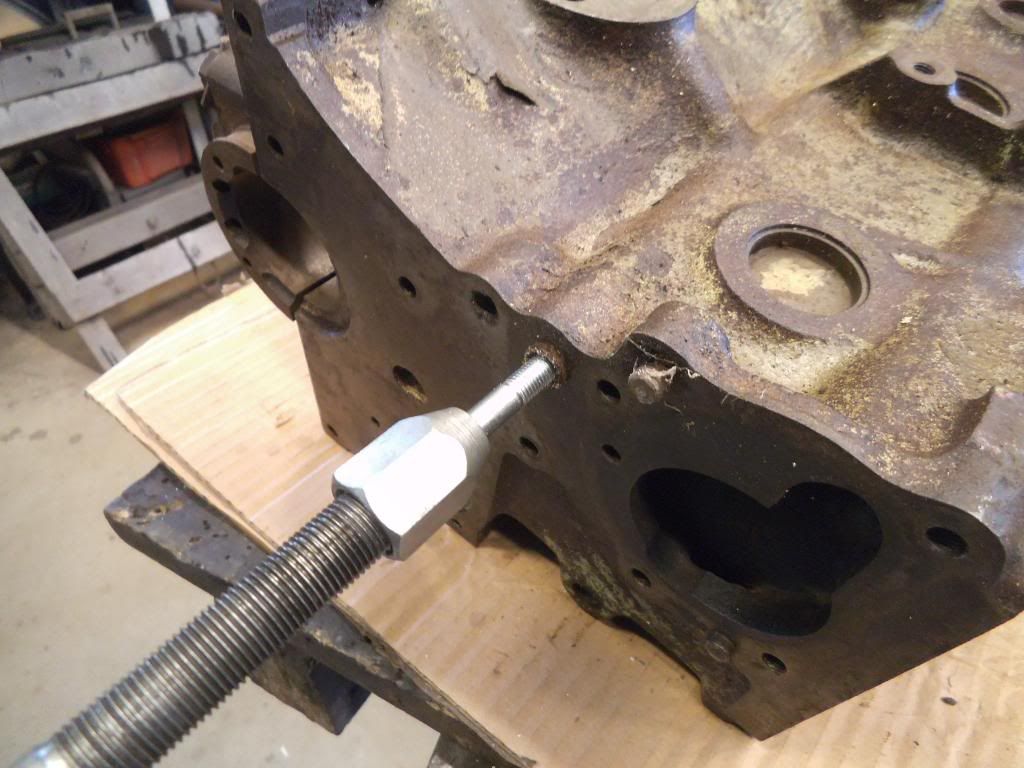

I start off by drilling one of the plugs;-

then tapping them 5/16" - this is a size somewhat smaller than the drilling for the plug;-

I don't ever try to drill them right out. If the drill wanders or isn't centred, there's a risk of damaging the drilling and then they'll never seal.

Then fit the slide hammer and pull the plug;-

Then I put an 8 mm rod right through to knock out the other plug;-

I'll also pull all the Freeze Plugs too;-

And the Oil Pressure Relief valve Seat;-

At this point I have the block 'dipped' to chemically clean it and then off to the machine shop

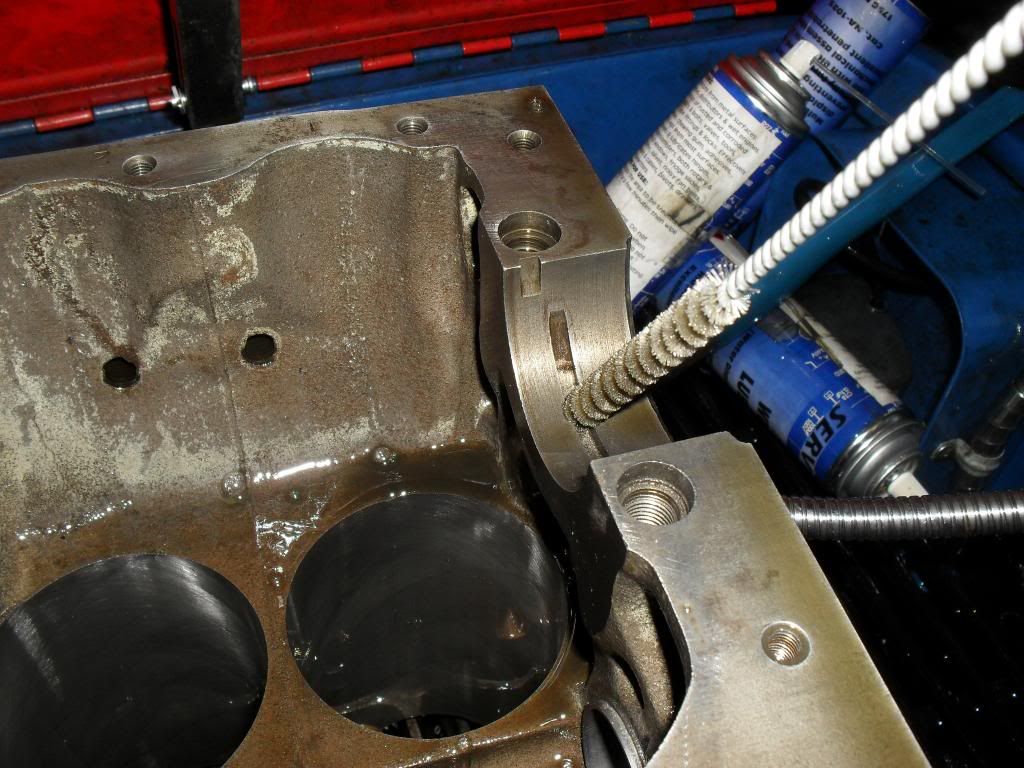

After coming back from the machine shop, to plug the galleries up again, I tap the holes M14, started off in the drill press, turned by hand to get them square

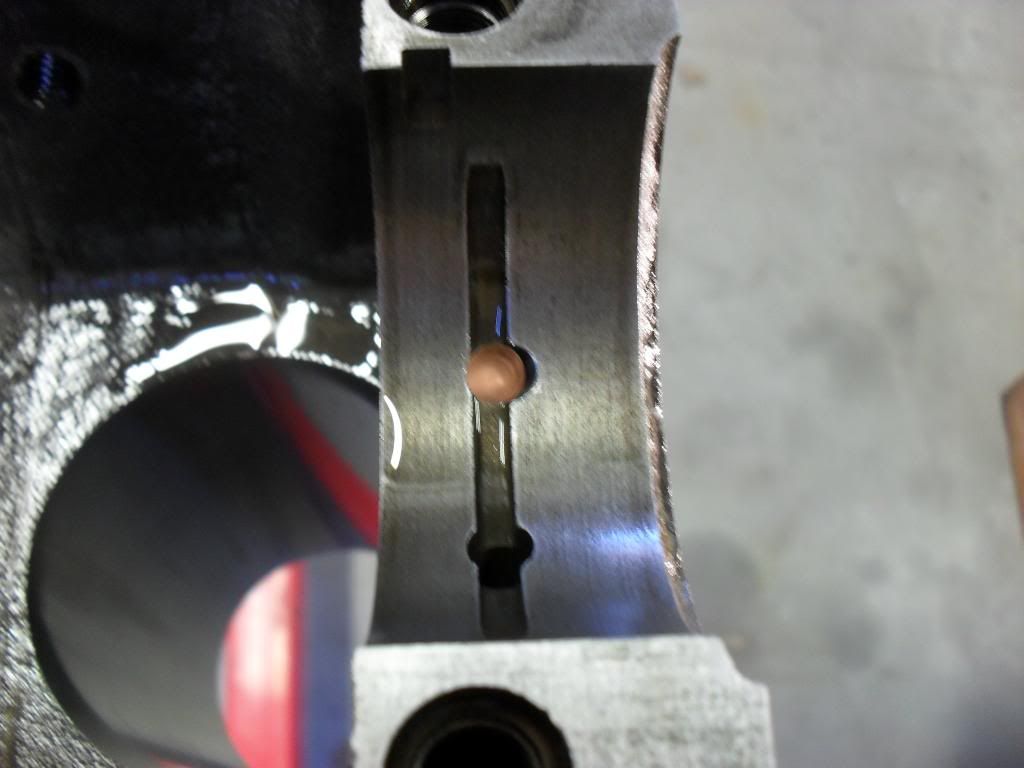

I can then easily clean the galleries;-

and Inspect them;-

fit Cup Point Grub Screws

with Loctite, to seal them up

While I fit removable threaded plugs, this isn't necessary to go this way, pressed plugs, like the factory ones can be fine, however some considerable care and caution should be used when fitting them, that they don't get shaved when fitting them as the swarf can end up inside the gallery, defeating the purpose of this exersize. They should be fitted with sealant (loctite is good for this) and even 'staked' to prevent them for coming out.

Edited by Moke Spider, 21 June 2016 - 08:11 AM.

#6

Posted 21 June 2016 - 07:54 AM

I like it

#7

Posted 21 June 2016 - 09:34 AM

FS

#8

Posted 21 June 2016 - 12:29 PM

I fitted plugs made from cut down m14 fine thread set screws with a slot cut for a flat bladed screwdriver for fitting my my block, but me being me I used some loctite that I had sitting on a shelf. The result was a fail as the thread lock had gone out of date. Engine had to be removed, dismantled and the plugs removed cleaned again with thinners and re-fitted with NEW threadlock. All tight now. Well at least that bit is tight!

#9

Posted 21 June 2016 - 01:08 PM

Spider excellent write up and photos for this work

you might like to add that extreme caution is needed in the length of the new threaded plugs as if they are too long they

block off other passages and cause terrible damage

very nice with the pictures too

#10

Posted 21 June 2016 - 03:57 PM

#11

Posted 21 June 2016 - 06:53 PM

I always pull the Main Oil Gallery plugs as a minimum in any engine build. I do think you can properly clean and then inspect all the Oil ways any other way.

I start off by drilling one of the plugs;-

then tapping them 5/16" - this is a size somewhat smaller than the drilling for the plug;-

I don't ever try to drill them right out. If the drill wanders or isn't centred, there's a risk of damaging the drilling and then they'll never seal.

Then fit the slide hammer and pull the plug;-

Then I put an 8 mm rod right through to knock out the other plug;-

I'll also pull all the Freeze Plugs too;-

And the Oil Pressure Relief valve Seat;-

At this point I have the block 'dipped' to chemically clean it and then off to the machine shop

After coming back from the machine shop, to plug the galleries up again, I tap the holes M14, started off in the drill press, turned by hand to get them square

I can then easily clean the galleries;-

and Inspect them;-

fit Cup Point Grub Screws

with Loctite, to seal them up

While I fit removable threaded plugs, this isn't necessary to go this way, pressed plugs, like the factory ones can be fine, however some considerable care and caution should be used when fitting them, that they don't get shaved when fitting them as the swarf can end up inside the gallery, defeating the purpose of this exersize. They should be fitted with sealant (loctite is good for this) and even 'staked' to prevent them for coming out.

Awesome post Moke, not something I hope to have to do anytime soon but very interesting reading!

One question though, I don't understand what you mean when you say they should be "staked" I tried a Google but didn't find much :-(

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users