Oil In Cylinders, And Pitted Piston?

#1

Posted 26 May 2010 - 01:21 PM

However, earlier on, when i took the spark plug out of number one cylinder, it was oily.

Then today, when i took the head off, there was a small puddle of oil in number one cylinder.

And the exhaust port for the number one cylinder was oily.

None of the head nuts felt as if they were done up tight enough.

The faces of the block and head look at if they have a little corrosion (not pitting).

And finally, number three piston is badly pitted.

So, there are the problems. I'm thinking the combination of the condition of the faces and the slackness of the nuts, probably led to the oil in the cylinders (all of them were very cokey, but number one was the only one was wet with oil). This can probably (hopefully) be solved by cleaning up both surfaces and tightening up the head nuts properly. However, the pitting of the piston has got me confused. Can anyone tell me what could cause this, and whether the engine's knackered??

I'll post up pictures as soon as photobucket starts working again.

Cheers, Paul.

#2

Posted 26 May 2010 - 01:25 PM

#3

Posted 26 May 2010 - 01:27 PM

I'll have pictures up shortly, photobucket just started working again.

Any ideas what can cause this business??

#4

Posted 26 May 2010 - 01:29 PM

#5

Posted 26 May 2010 - 01:32 PM

#6

Posted 26 May 2010 - 01:35 PM

I shall strip the valves and springs from the head, and check for any play in the valve guides, cheers.

Any other possibilities??

#7

Posted 26 May 2010 - 01:37 PM

#8

Posted 26 May 2010 - 01:41 PM

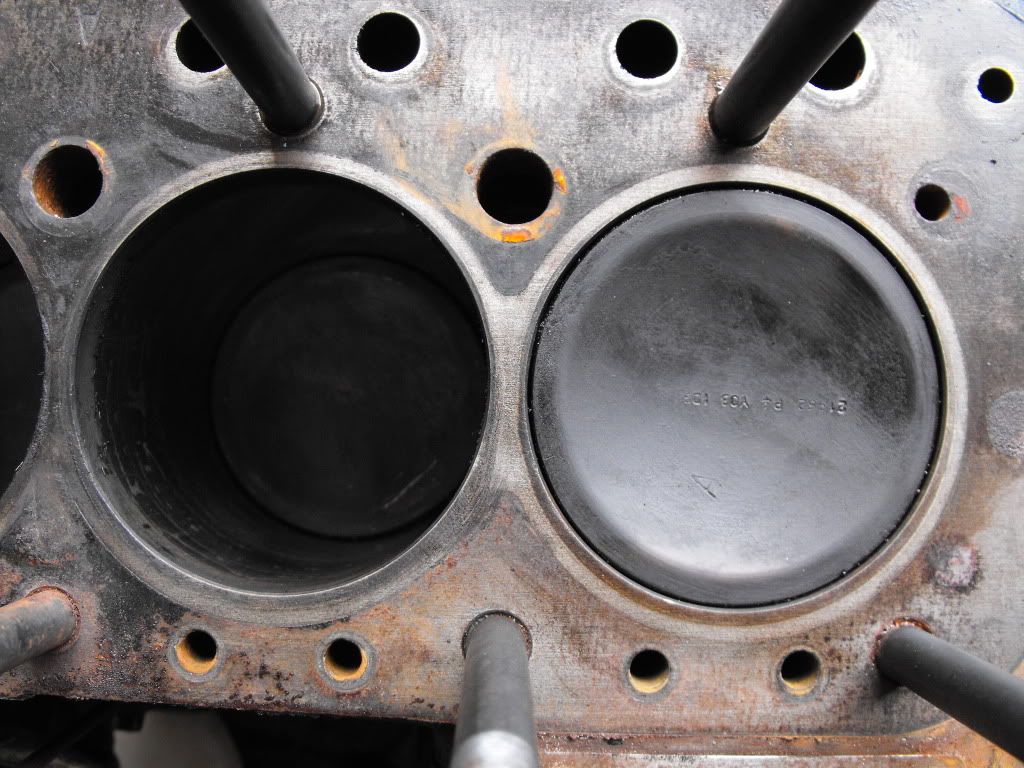

Picture of number one piston, this one had a puddle of oil, but cleaned up well:

Number one cylinder was the oily one here:

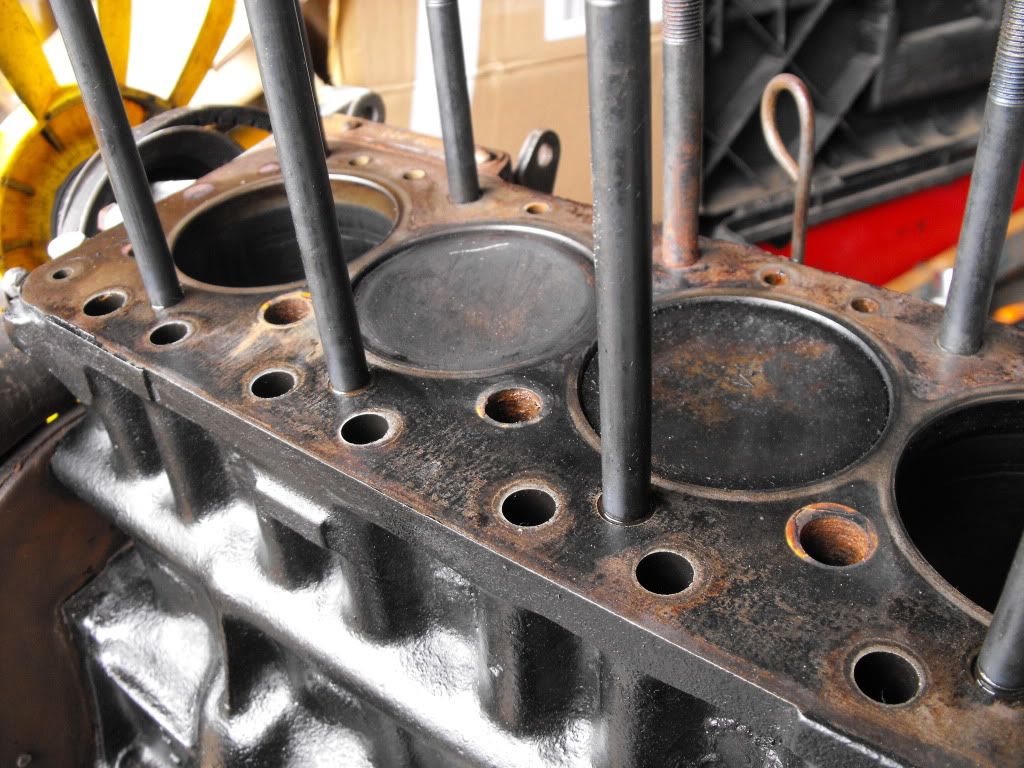

Here you can see the state of the mating faces. In need of a skim, do you think?:

Number four piston, not that bad:

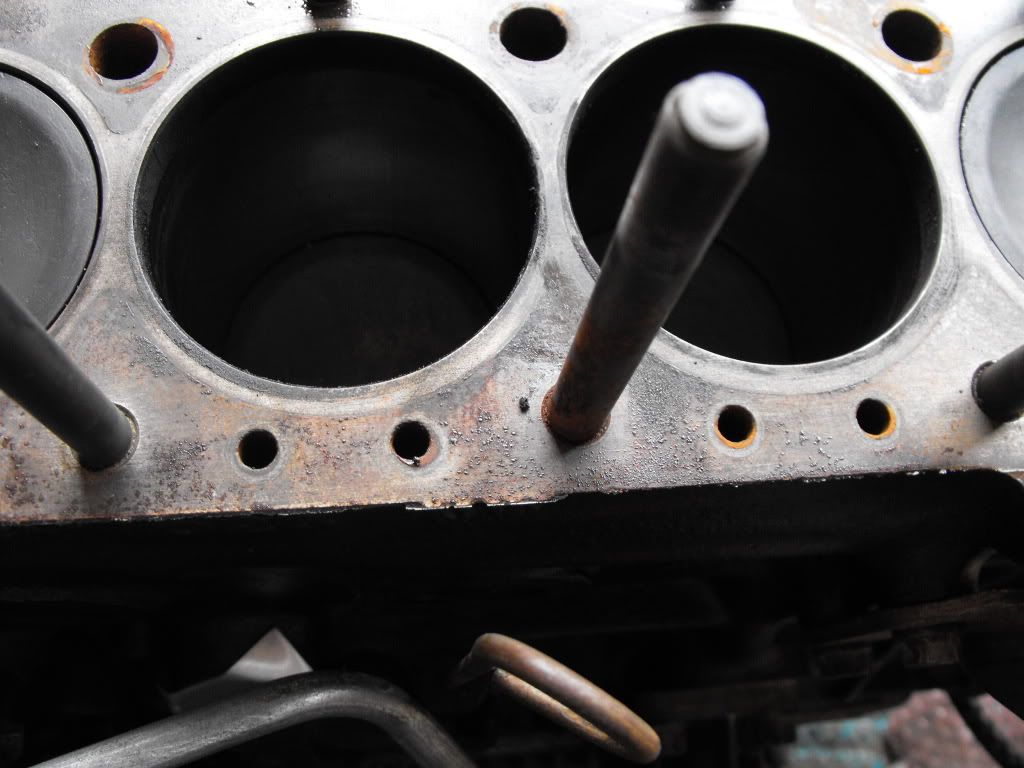

Pictures of bores:

Block face:

Edited by MiniLandy, 26 May 2010 - 01:44 PM.

#9

Posted 26 May 2010 - 02:31 PM

Your oil in number one could be worn valve guides, valve stem seals or piston rings. It could also be a combination of the three.

IMHO valve guides do not get replaced anywhere near as often as they should leaving your stem seals to struggle. New guides (iron) cost very little and are not beyond the scope of most people to replace. All you need in a set of vernier calipers and a suitably sized drift (once you've got the head apart). Once replaced, use a good quality Viton stem seal.

To get an indication of the state of your rings you really need to perform a compression test.

And the faces really do look in need of a skim

#10

Posted 26 May 2010 - 03:17 PM

I'll strip the head, check the valve guides for wear (and change if needed), change the seals, get it skimmed, and lap them back in.

Then i'll clean up the block face with a long flat blade or something, and put a good quality head gasket on. Then do a compression test.

Then either use it, or cry, depending on the state of the rings.

Anything i've missed, chaps and chapettes?

#11

Posted 26 May 2010 - 04:44 PM

dave

#12

Posted 26 May 2010 - 04:46 PM

#13

Posted 26 May 2010 - 05:19 PM

time for a rebuild thats knackered due to either running lean or ing timing up the wall when run, thoses little pits in the pistons is the psiton rings caused by detination from poor set up

dave

Due to the coking of the head, i would have said it's been running rich...

How are the pits caused by the piston rings??

Surely if the rings were that shot that bits of them had caused that pitting, i would be looking for scoring of the bore too??

The pitting doesn't look the sort from det, but i'm not really sure. What else should i be looking for, for signs of excessive det?

Don't mean to sound skeptical, but i would have expected more damaged from knackered rings.

#14

Posted 26 May 2010 - 11:47 PM

#15

Posted 27 May 2010 - 03:43 PM

I'd rule out timing as a cause of detonation beacuse all of your other pistons look much better than No3 and timing should be reasonably consistent...

What type of carburation was on this engine previously? If there were twin choke carbs on there it is possible to make the mixture on one pair of cylinders richer or leaner compared with the other pair. On looking back at your pictures there does seem to be some marking on No4 also... Because of the siamese ports on the mini the inner cylinders tend to run leaner than the outer cylinders. So if twin carbs were fitted and the mixture to 3 & 4 was on the lean side No3 would be more prone to detonation than No4...

That said the engine may also have gulped something and it's been rattling around in there for a while (by a while I mean a few seconds) and then been spat out the exhaust valve. As the induction stokes for 3 & 4 are right after one another it's entirely possible No3 picked up the worst of it and No4 got the dregs.

All of this aside... If the piston still looks to be as strong as the day it was made, the bore is in good condition and you get positive results from a compression test it doesn't really matter what has happened. Let's just make sure it doesn't happen again

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users